205mm Cordek Cellvent HX Ground Heave Cellular EPS Void Former - Grade 9/13 - 1200mm x 2400mm

- Product Code: A1-5625

- Delivery Time: 3 - 5 days

- Brand: Cordek

- Model and Size: 1200mm x 2400mm - 2.88m2

4.7 out of 5 - Excellent

205mm Cordek Cellvent HX Ground Heave Cellular EPS Void Former - Grade 9/13 - 1200mm x 2400mm

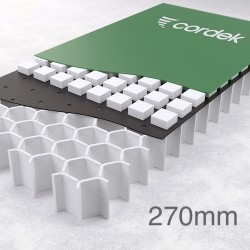

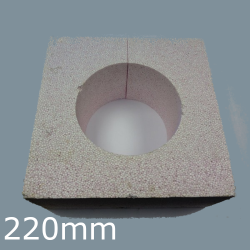

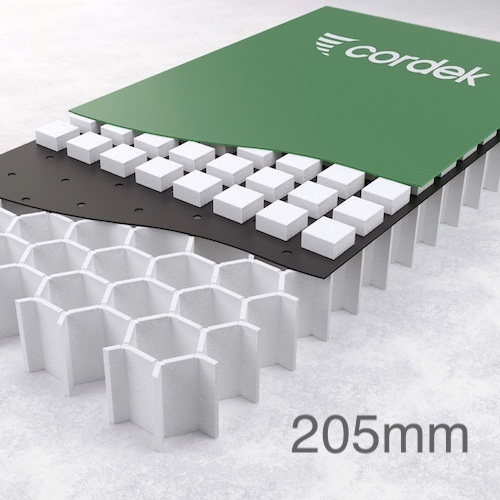

205mm Cordek Cellvent HX - Grade 9/13 is a product specially designed to provide foundation protection from ground heave effects whilst also providing an excellent gas venting medium when installed under reinforced concrete floor slabs where subsidence is not expected. Cellvent HX provides protection against ground heave, which occurs when expansive soils (such as clay) swell due to moisture changes, exerting upward pressure on structures. Cellvent HX is unaffected by UV light and water. In addition to ground heave protection, Cellvent HX serves as a passive gas venting system. It allows gases (such as radon) to escape from the ground, enhancing safety.

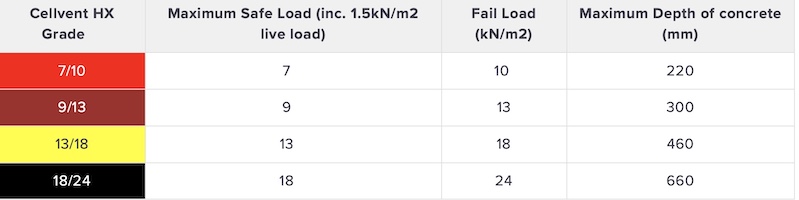

- The grade of Cellvent HX depends on the depth of the concrete slab.

- For example, the 9/13 grade has a maximum safe load of 9 kN/m² and a fail load of 13 kN/m².

- The maximum depth of concrete for this grade is 300 mm.

- Used beneath reinforced concrete floor slabs to provide a combined ground heave protection and passive gas venting system

- Available in a number of grades, suitable for different applications,

- Moulded for consistent performance and durability,

- Reduced depth and therefore less excavation,

- Less upward force is transmitted to the structure,

- Unaffected by both UV light and water,

- Suitable for most lightweight slabs,

- Cost effective and reduced carbon footprint,

- Highly durable and easy to work with,

- BBA certified and in accordance with the NHBC’s Technical Standards.

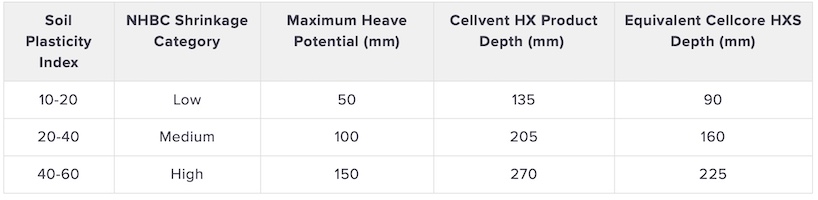

Tables for determining the most appropriate depth and grade of Cellvent HX panel, based upon the characteristics of the expansive soil type and the proposed thickness of the reinforced concrete slab:

For depth,

For grades,

INSTALLATION

- The Cordek Cellvent HX can be installed in a quite straightforward procedure, with standard precautions and safety procedures followed, as specified for EPS boards.

- Ensure the ground is level and compacted.

- Lay a suitable membrane (such as a damp-proof membrane) over the prepared ground.

- Place the Cellvent HX panels directly on the membrane.

- Align the panels to cover the entire area where the concrete slab will be poured.

- Leave a gap of approximately 10 mm between adjacent panels to allow for expansion.

- Use spacers or shims to maintain consistent spacing.

- Pour the concrete directly onto the Cellvent HX panels.

- The panels will become embedded in the concrete as it sets.

- Finish the concrete surface as usual (e.g., troweling, floating, or brushing).

- Ensure that the Cellvent HX panels remain undisturbed during this process.

- Follow standard curing procedures for the concrete slab.

- Certified under BBA, certificate number 11/4862;

- in accordance with the Building Regulations 2010 (England and Wales), the Building (Scotland) Regulation 2004 (as amended) and the Building Regulations (Northern Ireland) 2000 (as amended);

- in accordance with the NHBC’s Technical Standards.