EPS Polystyrene for Insulated Render

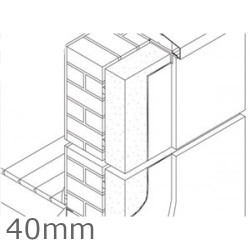

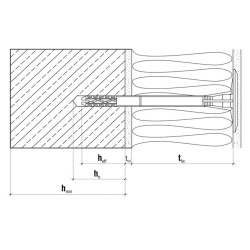

Thermal insulation of an external wall using a contact method is one of the traditional methods of wall insulation. It can be performed perfectly in both new and reconstructed building. Solid expanded polystyrene (EPS) insulating boards are glued onto the external wall and anchored mechanically and then a thin layer of coloured plaster is applied. Contact insulation is used most frequently in buildings built of bricks but may also be used successfully in modern wooden houses.

The solid wall insulation must achieve a U-value of 0.30 W/m2k, hence at least 90mm of expanded polystyrene insulation needs to be used. Obviously the thicker the material, the better its insulating performance. Expanded polystyrene is one of the least expensive, most cost effective rigid foamed plastic insulations and is an excellent material for wall insulation applications that come with a restricted budget.

Grey Polystyrene (Graphite) is a high quality expanded polystyrene (EPS) board enhanced with integrated graphite within its bead structure. The high-purity graphite particles integrated within the insulation beads reflects radiant heat and significantly improves insulation capability, providing up to 20% greater r-value than traditional white EPS of the same thickness. Warm air always moves towards cold air, In Grey Polystyrene (Graphite) the path taken by warm air moving towards the cold air takes many twists and turns along the way, slowing down the heat transfer, keeping the premises warmer.

CHARACTERISTICS

- Low thermal conductivity - Due to its closed air-filled cell structure that inhibits the passage of heat or cold, a high capacity for thermal insulation is achieved,

- Lightweight and ease of handling and installation,

- Low water absorption - does not absorb moisture and its thermal and mechanical properties are unaffected by damp, humidity or moisture,

- Chemical resistance - polystyrene is completely compatible with other materials used in construction including cements, plasters, salt etc.,

- Ageing resistance - material's properties are retained will last as long as the building itself, if properly installed,

- Polystyrene is not altered by external agents such as fungi or parasites as they find no nutritional value in the material.