Void Formers

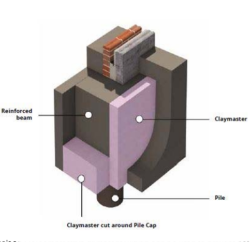

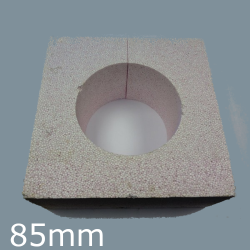

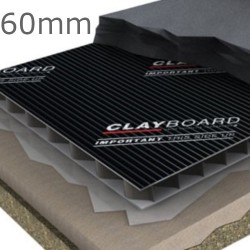

Void spaces (gaps) are designed to provide an intended buffer zone or clearance between expansive soils and a concrete foundation in order that heave can occur without imposing detrimental uplift pressures to the foundation. Such voids are filled with expanded polystyrene compressible-fill material and/or specialised honeycomb materials. While the expanded polystyrene would compress and uncompress taking away the soil heave stress from the foundation and the foundation slab, the proprietary honeycomb system is a collapsible system, which would leave space under the foundation slab, after the honeycomb is bio-degraded. The honeycomb system is used usually under foundation slabs. Void formers under the grade beams will typically be required if the uplift forces from the soil are greater than the dead load plus sustained live load of the foundation and superstructure.

Advantages

- A foundation slab with void space below allows expansive soils to swell into the void space, thereby reducing the risk of foundation heave.

- Foundation slabs that are elevated above the surrounding grade are less affected by surface water prior to concrete placement.

- Allows to build on sites with inadequately compacted, untested soil or other soil conditions that may not be suitable to support the construction of grade-supported foundations.

- Creates a path for water to migrate below the slab, particularly when the bottom of the void space is near or below adjacent grade.

- Usually increases cost of the design and construction.

- Concrete may enter the honeycomb form or the expanded polystyrene during placement, if any stakes are driven through them, or any space left between them.

- Lightweight structural void fill,

- Lateral load reduction on structures,

- Lateral and dead load reductions over buried utilities,

- Soft soil remediation,

- Slope stabilization

- Can be used where the use of larger mechanical equipment may not be feasible.

- Project construction time is reduced.

- Can be installed during any type of weather or site conditions.

- Project construction time is reduced as it is lightweight.

- Concrete, soil or any other material can be placed directly on EPS, eliminating formwork.