60mm Rockwool Ablative Coated Batt

- Product Code: A1-1287

- Delivery Time: 1 - 2 days

- Brand: Rockwool (Tech. support: 08712221780)

- Model and Size: 1200mm x 600mm - 0.72m2

- Weight: 6.91kg

- Currently: 50 in stock

60mm Rockwool Ablative Coated Batt

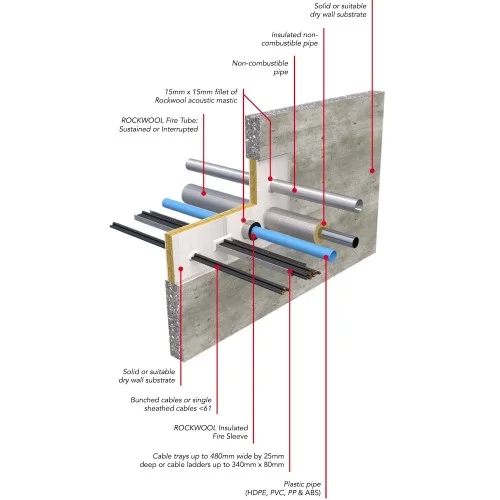

60mm Rockwool Ablative Coated Batt is a mineral wool insulation product that is pre-coated on both sides with an ablative layer. It has undergone extensive testing as part of the Rockwool FirePro range of fire-stopping solutions and can be installed across a variety of services and substrates, including solid walls and floors, flexible walls, multi-service penetrations, the head of the wall, blank seals, face-fixed applications, and large framed service voids. The Ablative Coated Batt is tested to provide up to four hours of fire resistance while also delivering acoustic performance and, importantly, maintaining airtightness to minimise unwanted heat loss. It is important to note that Ablative Coated Batts are not designed for use as load-bearing seals.

The tests have proved the capability of a single 60mm Batt to provide up to 4 hours fire resistance integrity, insulation ratings are dependent upon the service penetration.

- Fire resistant, offering resistance up to four hours,

- Very lightweight and easy to install,

- Compatible with a wide range of materials,

- Maintenance free,

- Proven acoustic performance,

- Provides air tightness and creates a smoke seal,

- Can be used as blank seal.

Rockwool Ablative Coated Batts are used to maintain fire resistance and acoustic performance of masonry walls, drywall systems and concrete floors, by either filling the voids created by services such as pipes, ductwork and cables or by filling blank voids.

INSTALLATION- Trim the batts to the required size.

- Use Acoustic Intumescent Sealant to apply a bead around the external edges of the batts.

- Insert the batts between the services and the edges of the wall or floor, ensuring a complete seal of the void.

- For butt joints between adjacent batts:

- Apply Acoustic Intumescent Sealant and/or FIREPRO Glue to both mating edges.

- Ensure a fire-tight bond is formed between the individual pieces of insulation.

- Use FIREPRO Acoustic Intumescent Sealant to point all joints, including those around the perimeter of the batt, to complete the seal.

For Plastic Pipes (PVC, ABS, HDPE, etc.):

- Use FIREPRO Insulated Fire Sleeves at the points where they pass through the Ablative Coated Batt.

For Metal Pipes (Steel, Copper, etc.):

- Insulate with a 1m length of ROCKWOOL Fire Tube or Pipe Section (minimum 40mm wall thickness), ensuring it protrudes equally from both faces of the Ablative Coated Batt.

- Use FIREPRO Sealant to point the joint between the Ablative Coated Batt and the pipe insulation.

Additional Considerations:

- If the pipe is thermally lagged with combustible insulation, cut it away and replace it with ROCKWOOL insulation as described above.

- Ensure the integrity of any vapour control layer is restored as necessary.

- Point the joint between the batt and the Fire Sleeve or Fire Tube with FIREPRO Sealant.

Please note that Rockwool Firepro Ablative Coated Batts are not intended to be used as load/bearing seals.

CERTIFICATION- BS EN 1366-3: 2009 and the dedicated fire resistance standard for linear joint seals, BS EN1366-4:2006.

- Ablative Coated Batt has been classified in accordance with BS EN 13501-2.

- CE marked to EAD 350454-00-1104.