Plasterboards with Insulation

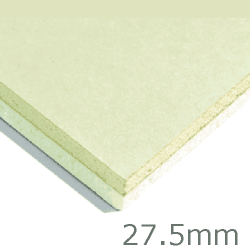

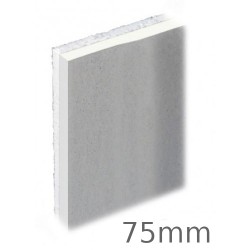

- PIR Insulated Plasterboard,

- Polystyrene Insulated Plasterboard,

- Phenolic Insulated Plasterboard

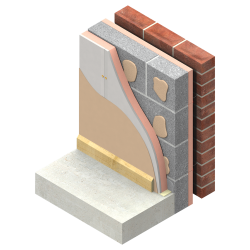

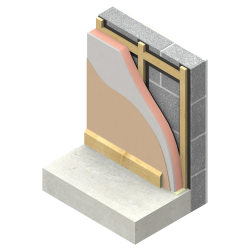

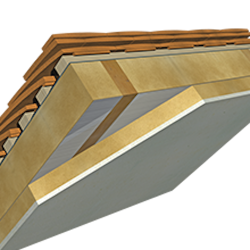

Whilst most new walls are suitable for dry-lining, the condition of the existing walls must be properly assessed and any necessary remedial work undertaken to ensure that the walls are dry, clean and free from any protrusions. Depending on the build quality and the materials used to build them, different methods must be used to ensure that the thermal laminates can be fixed successfully.

- All walls should be assessed as to whether they are suitable for dry-lining,

- All plasterboards should be fixed to walls that are dry,

- All boards should besecured to the wall with a minimumof two fire proof fixings,

- Avoid running electricalcables within the insulation layer,

- Ensure thatadequate ventilation is retained in therooms into which the thermal liners arebeing applied,

- Using the correctthickness of insulation, and the designand use of the heating and ventilationsystem correctly will avoid theoccurrence of surface condensation.

- Adhesive bonding of the Thermal Liners can be made to most masonry surfaces, if the walls are plumb and in good condition.

- Existing plastered walls that are in good condition will also accept the adhesive dabs,

- Any painted surface should be sanded back and treated with a PVA adhesive before applying adhesive dabs.

- Ribbons of adhesive should be placed around all wall edges and all openings and services on the wall to provide a fire stop and avoid air movement behind the thermal laminates.

In many instances, older walls are not suitable for dot and dab application because they present an uneven surface. In such situations, the application of insulated plasterboards using a mechanically fixed system onto timber framing/battens or a metal furring system might be appropriate to provide a level surface. They can also be mechanically fixed directly onto an even wall.