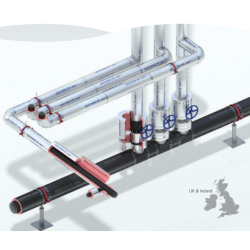

Pipe Insulation

Where pipes operate at below-ambient temperatures, water vapour would condense on the pipe surface. Moisture is known to contribute towards many different types of corrosion, so preventing the formation of condensation on pipework is important. Pipe insulation can prevent condensation forming, as the surface temperature of the insulation will vary from the surface temperature of the pipe.

Some water pipes are located either outside or in unheated areas where the ambient temperature may occasionally drop below the freezing point of water, any water in the pipework may potentially freeze. When water freezes, it expands due to negative thermal expansion, and this expansion can cause failure of a pipe system. As pipework can operate at temperatures far removed from the ambient temperature, heat flow from pipework can be considerable. In many situations, this heat flow is undesirable. The application of thermal pipe insulation introduces thermal resistance and reduces the heat flow.

Where pipework is operating at extremely high or low temperatures, the potential exists for injury to occur should any person come into physical contact with the pipe surface. As the surface temperature of insulation varies from the temperature of the pipe surface, pipe insulation can be used to bring surface touch temperatures into a safe range. Pipework can operate as a conduit for noise to travel from one part of a building to another. Acoustic insulation can prevent this noise transfer by acting to damp the pipe wall and performing an acoustic decoupling function wherever the pipe passes through a fixed wall or floor and wherever the pipe is mechanically fixed.

Pipe insulating Materials - Hot and Cold Applications

Glass: Service temperature range is up to 535°C.

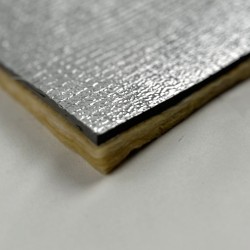

Rock and Slag: Rock and slag fibres are bonded together with a heat resistant binder to produce mineral fibre or wool. Upper temperature limit can reach 1035°C.

Available in board and block form capable of being fabricated into pipe covering and various shapes. Service temperature range is -260C to 200°C and to 650°C in composite systems. Good structural strength, poor impact resistance. Material is non-combustible, non-absorptive and resistant to many chemicals.

Calcium Silicate is a granular insulation made of lime and silica, reinforced with organic and inorganic fibres and moulded into rigid forms. Service temperature range covered is 35°C to 815°C. Flexural and compressive strength is good. Calcium silicate is water absorbent. However, it can be dried out without deterioration. The material is non-combustible and used primarily on hot piping and surfaces. Finishing material is applied on site.

Perlite is made from an inert siliceous volcanic rock combined with water. The rock is expanded by heating to above 535°C causing the water to vaporize and the rock volume to expand. This creates a cellular structure of minute air cells surrounded by vitrified product. Added binders resist moisture penetration and inorganic fibres reinforce the structure. The material has low shrinkage and high resistance to substrate corrosion. Perlite is non-combustible and operates in the intermediate and high temperature ranges. The product is available in rigid pre-formed shapes and blocks.

Foamed resins combined with elastomers produce a flexible cellular material. Available in pre-formed shapes and sheets, elastomeric insulations possess good cutting characteristics and low water and vapour permeability. The upper temperature limit is at 105°C. Elastomeric insulation is cost efficient for low temperature applications with no cladding necessary. Resiliency is high. Consideration should be made for fire retardancy of the material.

Insulations produced from foaming plastic resins create predominately closed cellular rigid materials. Lambda values decline after initial use as the gas trapped within the cellular structure is eventually replaced by air. Foamed plastics are light weight with excellent cutting characteristics. Foamed plastics are generally used in the lower intermediate temperature range. Consideration should be made for fire retardancy of the material.

Refractory fibre insulations are mineral or ceramic fibres, including alumina and silica, bonded with extremely high temperature inorganic binders, the mechanical interlocking of fibres eliminates the need for any binder. The material is manufactured in blanket or rigid form. Thermal shock resistance is high. Temperature limits reach 1750 °C. The material is non-combustible.

Rigid closed cell foamed insulation manufactured from phenolic resin.

- Insulation products should only be applied to pipe work which is clean, dry and unheated.

- Do not compress pipe insulation sections at joists, studs, columns, ducts etc. This is important because any insulation loses some of its insulation value if it is compressed. On cold pipes condensation may occur where the insulation is compressed.

- Space should be allowed around pipe work to help air circulation. Air movement is an extra safeguard against condensation on cold pipes especially in hot, humid weather.

- Never stretch the pipe insulation sections. Always use the proper size of insulation for the job. Do not stretch it over the pipe. Butt-end joints can be made without stretching the lengths of insulation.

- Proper sealing of all pipe insulation is important to minimise heat loss and control condensation. On cold lines, open pipe insulation joints may allow the formation of condensate drip or contribute to possible pipe or tubing corrosion. All insulation joints should be sealed as shown in the insulation instructions.

Here at Insulation Shop you can find a various types and sizes of pipe insulation sections from leading manufacturers, such as Rockwool and Kingspan.