Paints

Paints consists of:

- Pigment - to impart colour and opacity,

- Binder - a polymer (resin) to hold the pigment in place,

- Extender - larger pigment particles added to improve adhesion, strengthen the film and also to save binder,

- Additives - to modify the properties of the liquid paint or dry film,

- Solvent - to reduce the viscosity of the paint for better application.

The binder and solvent together is the vehicle that carries the pigment, which gives the colour to the paint. Paints are made according to their proposed use; primer, undercoat and finishes. The pigment powder is broken down into individual particles, which are dispersed in the binder. Solvent is then added to give the required consistency. The most important binders used in modern paints are acrylic polymers, alkyd polymers and epoxy polymers. The solvent is either water, which is much better for the environment, or organic solvents.

Acrylic paint is fast drying paint containing pigment suspension in acrylic polymer emulsion. An emulsion is a mixture of two or more liquids that are normally immiscible (doesn't blend or mix). Acrylic paints can be diluted with water, and become water-resistant when dry. You can modify the appearance, flexibility, texture, and other characteristics of the paint surface by simply by adding water.

The surfaces covered with acrylic paint can be washed by hand and with appliances operating under low pressure. The acrylic paint may be applied on clean, dry and smooth surfaces free from any substances that decrease adhesion such as grease, bitumen, dust. Ceresit CT42 acrylic paint, for example, can be applied on concrete aged over 28 days, on traditional cement plasters, lime-cement plasters and lime plasters aged over 14 days, on mineral and mineral-polymer plasters aged over 7 days, on acrylic plasters aged over 3 days, on gypsum substrates, on gypsum cardboards, gypsum-fibre boards primed before with Ceresit CT17 primer. After only 15 minutes from the primer application, it is possible to move to the next stage of work, painting. Ceresit CT17 primer is highly recommended for aerated concrete, anhydrite and gypsum substrates and for priming chipboard and non-impregnated plasterboard.

- The area not to be painted, such as windows, doors should be protected with foil. If there are any plants etc., should be protected as well.

- The content of the container should be carefully stirred by means of the drill with a mixer for about 2 minutes.

- Usually it is sufficient to paint twice. Between the application of the subsequent layers the 4 - 6 hour technological breaks should be maintained.

- The paint should be applied evenly by means of a brush, roller or a sprinkling device.

- Most paints come ready to use without any dilution, but it is possible to add not more than 10% of water, if such a need arises.

- Work on one surface should be carried on without any breaks using the paint of the same badge number (printed on each packaging) or the content of containers with different badge numbers should be mixed together.

- Application should be performed in dry conditions with the ambient and substrate temperature ranging from +5 to +25 C and the humidity below 80 %. The drying of the paint depends on atmospheric conditions.

- Any stains should be immediately rinsed with water.

- Tools should be washed carefully with water directly after being used.

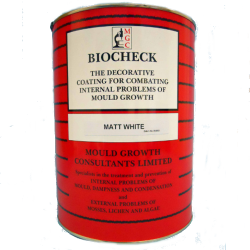

Silicone resin emulsion paints rank among the most modern exterior coating systems. The binder in silicone resin emulsion paints comprises mineral-based silicone resin and polymer emulsion. The silicone resin binders build up stable three-dimensional silicone resin networks on building surfaces and in coatings and make the paint highly water repellent and higher water-vapour permeability. It become chemically bound to the mineral substrate. Water is unable to penetrate and simply rolls off.

The structure of the coating ensures fast moisture evaporation from the substrate and at the same time creates an efficient protection against the substrate moisture and humidity. For example, the binder used in Ceresit CT 48 silicone paint causes pearl like effect of water after wetting the coat. Silicone additives bring the surface properties, such as anti-slip, abrasion resistance and can make to improve the sustainability of decorative coatings in architectural and wood coating applications.

The paint with extremely high hydrophobia is Ceresit CT49 Silix XD nano-silicone paint, which had been created with a proprietary formula. It would not only repel water, but also dirt and other contaminants and keep the surface sheen for a long time.

- The area not to be painted, such as windows, doors should be protected with foil. If there are any plants etc., should be protected as well.

- The content of the container should be carefully stirred by means of the drill with a mixer for about 2 minutes.

- Usually it is sufficient to paint twice. Between the application of the subsequent layers the 12 - 24 hour technological breaks should be maintained.

- The paint should be applied evenly by means of a brush, roller or a sprinkling device.

- Most paints come ready to use without any dilution, but it is possible to add not more than 5% of water, if such a need arises.

- Work on one surface should be carried on without any breaks using the paint of the same badge number (printed on each packaging) or the content of containers with different badge numbers should be mixed together.

- Application should be performed in dry conditions with the ambient and substrate temperature ranging from +5 to +25 C and the humidity below 80 %. The drying of the paint depends on atmospheric conditions.

- Any stains should be immediately rinsed with water.

- Tools should be washed carefully with water directly after being used.