Reflective Foil Insulation

Heat travels from a warm area to a cool area by a combination of conduction, convection, and radiation. Heat transfer by convection occurs when air is heated, becomes less dense, and rises. Radiant heat travels in a straight line away from any surface and heats anything solid that absorbs its energy. When the sun heats a roof, a large portion of this heat travels by conduction through the roofing materials to the attic side of the roof. A radiant barrier reduces the radiant heat transfer from the underside of the roof to the other surfaces in the attic. To be effective, it must face an air space. A radiant barrier works best when it is perpendicular to the radiant energy striking it. Also, the greater the temperature difference between the sides of the radiant barrier material, the greater the benefits a radiant barrier can offer.

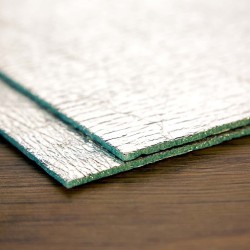

- Reflective foils - usually aluminium foils or plastics membranes laminated or coated with a reflective material.

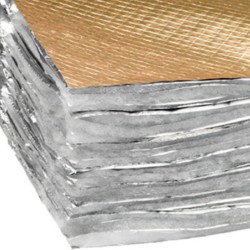

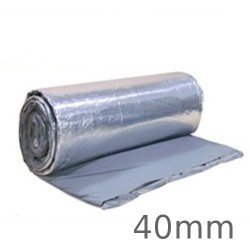

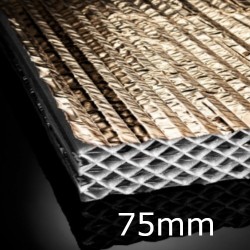

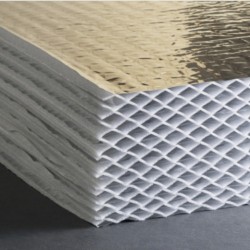

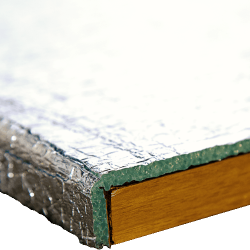

- Laminated membranes - composite, flexible materials comprising a series of lamination, which typically include aluminium foil; polyethylene sheet; mineral wool fleece; encapsulated polyethylene sheet (bubble wrap) or polypropylene membranes.

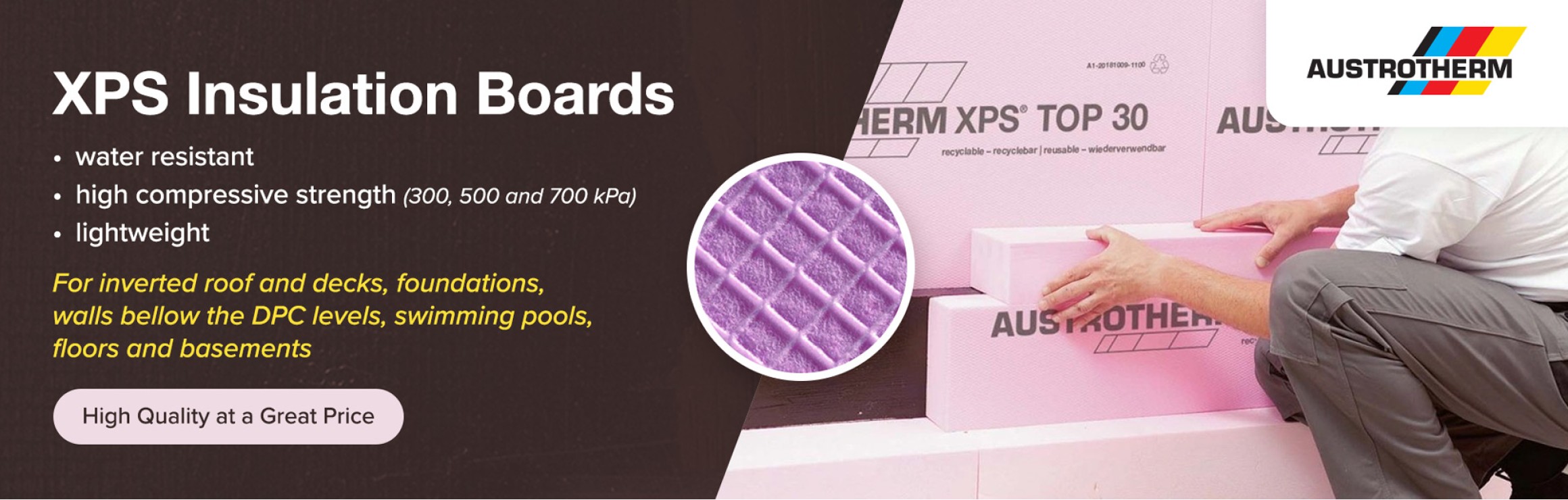

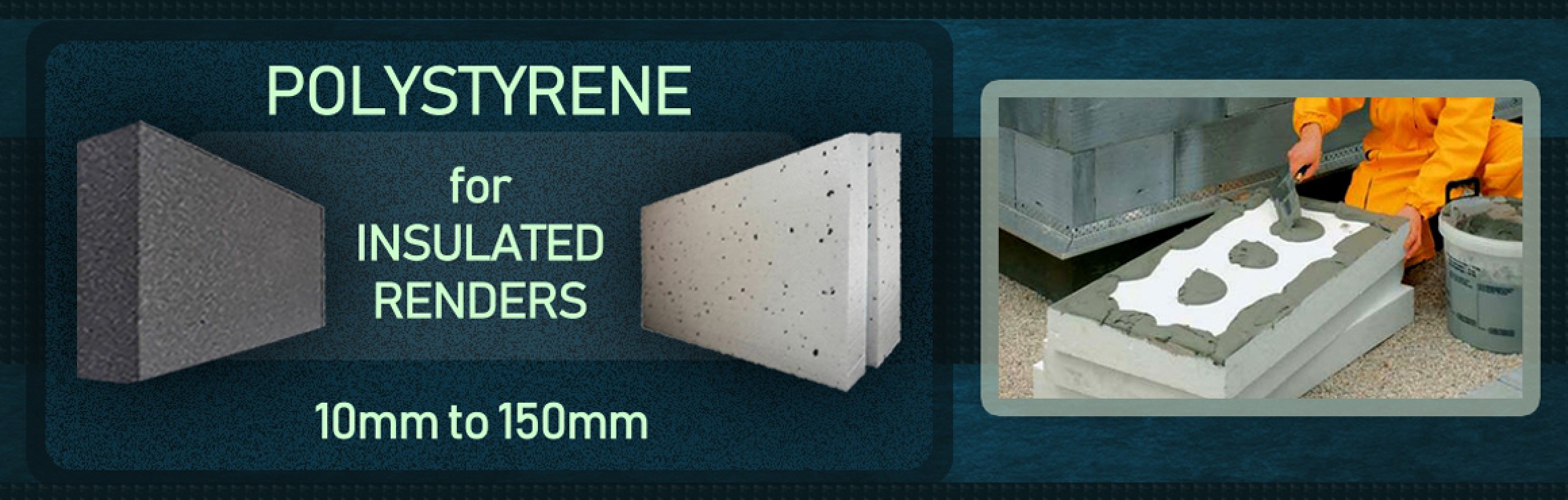

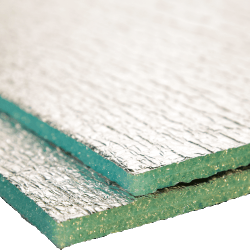

- Laminated boards - reflective foil laminated to rigid polyurethane, expanded or extruded polystyrene, or mineral wool boards or quilt.

- Sarking underlay,

- As an additional layer placed over conventional horizontal roof insulation,

- Suspended ground floor insulation draped over joists,

- Wall insulation suspended in vertical cavities,

- External solid wall insulation,

- Internal solid wall insulation,

- External timber frame insulation,

- Internal timber frame insulation,

- Insulated wrapping to ducting,

Multi-layer reflective foil insulation is recommended for use in a range of applications; their installation typically relying on the need for an adjoining cavity facing the surface reflective foil. They have a high vapour resistance, so may also function as a vapour control layer.