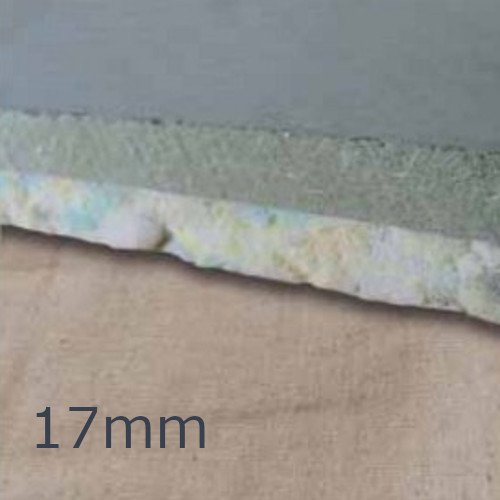

17mm Monodeck 17T Timber Floor Acoustic Overlay Board

- Product Code: A1-1288

- Delivery Time: 3 - 5 days

- Brand: Isomass (Tech. support: 08458383389)

- Model and Size: 1200x600mm - 0.72m2

- Weight: 5.10kg

17mm Monodeck 17T Timber Floor Acoustic Overlay Board

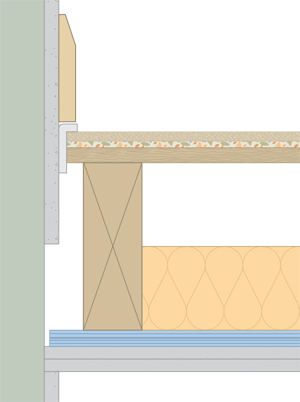

Monodeck 17T is an overlay platform system bonded direct to floorboards, designed for reducing sound transmission and improving acoustic performance of timber floors, whenever finished floor height is not critical. The system is used in new build, refurbishment and conversion applications, able to reduce impact sound transmission in wooden floors and able to meet the requirements of the Building Regulations, Approved Document E 2003 (including the subsequent amendments in 2004, 2010 and 2013). The system includes 9mm moisture resistant fibreboard bonded to 8mm Acoustic Chip Foam (ACF).

- Great acoustic properties;

- Able to reduce impact sound transmission in finished wooden floors;

- Able to meet values prescribed by the Approved Document E of the Building Regulations, when installed as part of a complete party floor construction;

- Includes a moisture-resistant chipboard.

Monodeck 17T is applicable over existing floorboards on timber joisted floors, in refurbishment, conversion projects and new build, with a new resilient bar ceiling.

- all invasive fittings must be properly treated;

- all structural wall should be sealed;

- the sub-floor, which must be clean and dry, should be covered with proper insulation layer consisting of mineral wool insulation, added between the floor joists;

- the entire structure needs to be watertight;

- the product must be kept and stored in dry conditions.

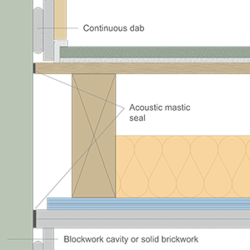

In order of reducing impact vibration leaking and reducing airborne sound paths, the edges of the Monodeck board should be covered with proper acoustic angled flanking band. The boards are then pushed against the wall perimeter, s that the board would be isolated from the wall.

Monodeck 17T is laid over existing floor board, in broken bond pattern and all grooved and tongued panel joists covered with proper adhesive. In case of any excessive adhesive, it should be removed with a damp cloth. Installation should begin with at the furthest point from the entrance, making sure that all the panels are at least 200mm wide, whereas no mechanical fixings are necessary. Finally, the boards should be properly covered upon installation with a protective layer, in order of avoiding potential damage.

It is important to fit the linings to door openings before installing the acoustic floor and to detail the boards properly, so they will ensure a good fit. Alternatively, stops and architraves can be added upon acoustic floor installation, with a 2/3mm gap from the floor surface.

When installing the boards in a bathroom, it is advised that the bath is supported on isolation pads and that the floating floor terminates as close as possible to the bath legs. Also, plywood should be installed under the bath and, if necessary, the joints should be filled with proper acoustic sealant. The same goes for installing Monodeck boards in a kitchen, where kitchen units should be installed on pads, allowing the Monodeck boards to end at the legs of the units.

In order of preventing flanking transmission, new ceiling boards should be installed before any dry-lining, either fixed to resilient bars or suspended from a metal frame system.

The product is in compliance with Approved Document E of the Building Regulations.