Loft Insulation and Ceiling Downlight Covers

by Mark Row

Taking Proper Care of Insulation

Although proper insulation of each part of a household is vital in the words of improved energy efficiency, money savings and lower carbon footprint, not to mention all other potential benefits, it often comes with a number of issues that need to be timely dealt with. If you have decided to add insulation to your loft space, then it is extremely important to consider all the potential issues connected therewith if you want to make sure that everything will function properly and that all risks will be determined, defined and put under control. Choosing the most suitable insulation material is the first step but when installing it into your loft space, you will have to consider all the installation glitches, as insignificant as they may seem at first. This especially goes for the loft insulation and ceiling downlight covers, since many studies have shown that these can be a source of fire hazards whenever recessed downlights are not properly covered and protected thus able to start a fire when they come in contact with the insulation material.

About Loft Insulation

Adding an insulation material to your loft is an inevitable part of a conversion or remodeling project and should never be taken lightly nor bypassed. It will add the stability and thermal insulation to your loft space which is particularly important if converted into a living space. You will also notice that the applicable Building regulations also prescribe the obligatory insulation values in loft and attic spaces which are achieved with adequate and recommended thickness of the chosen insulation material.

A number of insulation materials can be used for this purpose, depending on the result that one wants to achieve and the accessibility of the loft space. Most commonly loft insulation materials include bulk or fibre insulation (such as rock or glass wool which is laid between the roof joists in one layer and covered with another layer placed over the joists and the existing material, in order of meeting the prescribed insulation values. Another popular option is the blown-in insulation which uses specially designed equipment to blow-in the particles of insulation within the under-roof space and cover the entire area, making sure that no gaps are left in the insulation which can affect the effectiveness and functionality of the insulation added.

Now, when adding loft insulation, there are a number of things to take into account. Firstly, you must take proper care of any water tanks, cables or pipes going through the loft space and then adequate ventilation must also be provided. These issues must be dealt with not only because inadequate (or no) treatment can affect the insulation itself but also because some of them also bear some serious safety hazards, such as fire and moisture problems.

Why Downlights Must Be Properly Covered

If you have downlights installed and you are planning on adding insulation to your loft space, you will encounter a very common dilemma. Basically, downlights emit a level of heat, depending on the bulb used (you will notice that halogen and LED lights consume less energy and emit less heat), why they should not be exposed nor directly covered with any type of insulation, due to the risk of fire breaking out. Also, you will notice that there is a fire risk even if there is no insulation added, since the debris from the loft can settle onto the downlights just as there is a risk that the roof timber rafters may be easily ignited if constantly exposed to increased temperatures. This means that some space around the downlights needs to remain free and uncovered with insulation. On the other hand, this can affect the performance of the loft insulation added, since it will cause discontinuity in the insulation and affect the air tightness of the entire household. Namely, heat will travel up during the winter and escape through the uninsulated area in the ceiling just as heat will travel down and heat up the top floor during the summer.

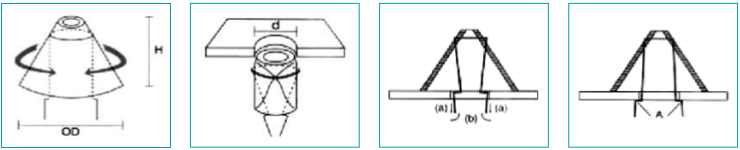

All the upper mentioned reasons have made the Electrical Safety Council conduct studies on fire safety of downlights which resulted in the fact that all downlights or adequate downlight covers when used in an insulated loft space must meet the requirements of the BS EN 60598 (have a look at the British lighting standards), in practice shown by the F-capped symbol. These caps and fire insulation covers will allow the insulation material to go directly over the downlights thus not affecting the air tightness of the material but not at the price of fire safety.

This is why it is extremely important to always carefully read the manufacturer’s instructions and information on installation and fire performance of a specific downlight. Namely, some are designed with the fire-protection already built in, sealing it and thus preventing the fire and smoke from spreading in an event of a fire. If this is not the case, adequate ceiling downlight covers must be provided. Some products can be directly fixed onto the normally flammable materials (materials having an ignition temperature of at least 200°C) such as wood. Others do not possess the named characteristics and should be properly protected, so always make sure to check the markings and symbols on the packaging. Another thing you should pay attention to is the IP rating (ingress protection) which depend on the location they are installed in (bathrooms for example).

The final word of advice on loft insulation and ceiling downlight covers is to always consult and engage a professional and certified electrician to install the downlights, to make sure that the equipment is not disturbed whenever you undertake any repair work and that insulation and downlights are successfully combined and compatible.

Take a look at the available loft insulation products we offer and pick the one that best fits your needs. Feel free to seek advice about the downlight covers from our experts by email, live chat or phone. You are welcome to leave a comment or share the article.