140mm Kingspan Styrozone H350R Flat Roof XPS Board (pack of 3)

- Product Code: A1-1184

- Delivery Time: 3 - 5 days

- Brand: Kingspan (Tech. support: 01544388601)

- Model and Size: H350R 140mm - 0.75m2

4.7 out of 5 - Excellent

140mm Kingspan Styrozone H350R Flat Roof XPS Board (pack of 3)

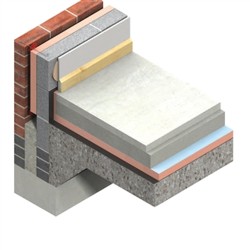

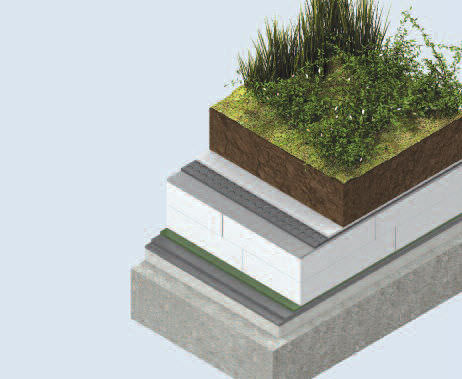

Kingspan Styrozone H350R Flat Roof XPS Board is highly effective rigid insulation board made from extruded polystyrene core covered with smooth skin on both sides. It is especially designed for protected membrane flat roofs, but is also used in green roofs as a popular alternative to traditional roofing systems, whereas its high comprehensive strength makes it ideal for inverted roofing. It is manufactured using 0 ODP and low GWP blowing agents, which also makes it highly environmentally friendly. Unlike fibre insulation materials which can be sensitive to water vapour, Styrozone H 350 R has a closed cell structure, which makes it not only water vapour and moisture resistant but also unaffected by air filtration, thus upgrading the thermal performance of the entire construction. It is most commonly used as a part of the protected membrane roofing systems, with a paving slab or a gravel finish or as a part of green roof systems. It is very easy to install and requires no maintenance, allowing additional insulation to be added later on, so what you will get is a roofing system protected from UV degradation, mechanical damage, and condensation.

Kingspan Styrozone H350R Flat Roof XPS Board is designed for protected membrane roofing systems and green roofs. It is suitable for use single-ply and mastic asphalt waterproofing membranes and also some cold and hot liquid applied waterproofing systems.

- Highly water and moisture resistant,

- Easy to cut and install,

- Especially designed for inverted roof systems and green roofs,

- High compressive strength,

- 0 ODP and low GWP potential,

- Low thermal conductivity,

- Non–deleterious material,

- Resistant to most dilute acids and alkalis.

The boards should be installed starting from the roof access point. They need to be laid either diagonally or with their long edges positioned at right angles to the edge, making sure that there are no gaps at abutments. In case you need to install more than one layer of insulation, make sure that the board joints do not coincide in any two adjacent layers. Horizontal roof insulation bottom and insulation upstand top should be kept at a minimal distance of 300mm.

The insulation boards should be covered with a non-woven polyethylene membrane which needs to be turned up at the insulation edge and properly sealed under the flashing. In order of providing adequate protection to the membrane, try to install the ballast layer as soon as possible, which needs to have minimum depth of 50mm and nominal 20-40mm diameter, properly washed and rounded prior to installation.

In case you have opted for paving slab ballast, it should be minimum 50mm thick and installed over the non-woven polyethylene membrane, laid on minimum 175 mm diameter slabs, in order of ensuring drainage is maintained below the slabs and that the excessive moisture can escape. Use nominal 20-40mm diameter rounded gravel to fill the gaps between upstand and the paving slabs.

- BS EN ISO 9001: 2000,

- Satisfies the requirements set out in the Control of Substances Hazardous to Health Regulations, 1988 (COSHH),

- Has FAA rating in accordance with BS 476–3: