Gypsum Based Boards

Gypsum board is the generic name for a family of panel products that consist of a noncombustible core, composed primarily of gypsum, and a paper surfacing on the face, back and long edges. All gypsum panel products contain gypsum cores, and can be faced with a variety of different materials, including paper and fiberglass mats. When joints and fastener heads are covered with a joint compound system, gypsum wall board creates a continuous surface suitable for most types of interior decoration.

To produce gypsum board, the calcined gypsum is mixed with water and additives to form a slurry which is fed between continuous layers of paper on a board machine. As the board moves down a conveyer line, the calcium sulfate recrystallizes or rehydrates, chemically combining with the water that was removed during calcination and reverts to its original rock state. The paper becomes chemically and mechanically bonded to the core. The board is then cut to length and conveyed through dryers to remove any free moisture.

- Ease of installation - Gypsum board panels are relatively large compared to other materials. It is a lightweight material. Gypsum board can be cut with either a utility knife or a variety of saws, and it can be attached with a variety of fasteners, including screws, nails, and staples. It can also be adhesively attached to many substrates. Gypsum board is easily finished using either a few hand tools or relatively modest machines.

- Durability - Gypsum board is used to construct strong, high quality walls and ceilings that offer excellent dimensional stability and durability. Surfaces created using gypsum board are easily decorated and refinished.

- Economical - Gypsum board is an inexpensive wall surfacing material that provides a fire resistant interior finish. Gypsum board building systems can generally be installed at significantly lower labor costs than most alternate systems.

- Fire resistance - Gypsum board is an excellent fire-resistive building material. Under normal atmospheric pressure, it very effectively retards the transfer of heat and the spread of fire. It has a low flame-spread index and a low smoke-density index. Gypsum board serves to effectively protect building elements from fire for prescribed time periods.

- Sound isolation - Gypsum board wall and ceilings systems effectively help control sound transmission, preventing the transfer of unwanted sound to adjoining areas is a key consideration when designing a building, specifically when taking into account the intended activities of the occupants in the various parts of the building.

- Versatility - Ease of application, performance, ease of repair, availability, and its adaptability to all forms of decoration combine to make gypsum board unmatched by any other surfacing product. Gypsum board satisfies a wide range of architectural requirements for design.

- Partitions,

- Lining of walls - concrete or masonry

- Ceilings,

- Lining steel structures

- Fire resistance - Gypsum is non-combustible and able to delay a fires spread up to 4 hours. Gypsum acts, in that case, as a fire barrier and thus reduces home or business fire damage.

- Humidity resistance - Gypsum is capable of storing humidity when a room is humid and automatically releasing this humidity if the indoor air becomes too dry. Small temperature increases are absorbed and radiated back later when the temperature in the room decreases.

- Sound insulation - Gypsum walls, ceilings and floors together with insulation materials create quiet zones in the house or business environment. They provide a physical barrier to sound, incorporate a sound break and minimize reverberation.

- Shock resistance - The plasterboards, gypsum fibreboards have a degree of hardness equivalent to a thick wall heavy masonry construction.

- Thermal Resistance - Thanks to its low thermal conductivity, Gypsum plasterboards contribute, together with the insulating material to the insulation of external walls and linings.

Gypsum board is easy to install and to dismantle - to construct an internal wall, for example, a frame is erected, plasterboard is fitted to it, joints are filled, and the wall is created. The operation is fast, clean, dry and uncomplicated.

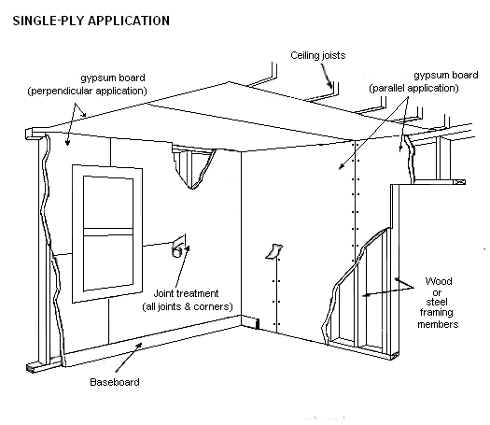

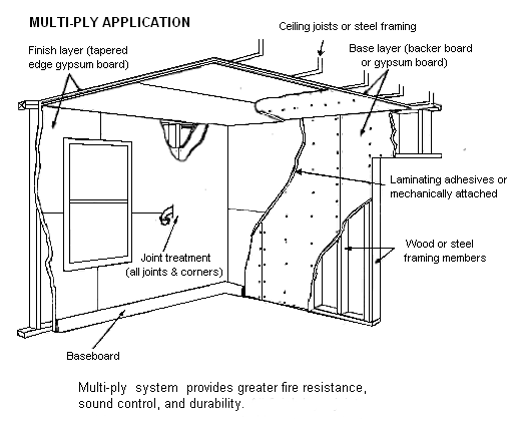

Gypsum board can be applied over wood or metal framing or furring. It can be applied to masonry and concrete surfaces, either directly or to wood or metal furring strips. When applying board directly to masonry or concrete surfaces, smooth or fill in any irregularities to ensure proper attachment and an acceptable final finished surface. Furring properly attached to interior sides of exterior walls provides flat surfaces for standard fastener application as well and sufficient separation from substrates to overcome dampness in exterior walls. Do not allow gypsum board to directly contact surfaces, such as concrete or soil, with potentially high moisture contents. Most common in residential construction is the gypsum wallboard system1in which the joints between the panels and internal corners are reinforced with tape and covered with joint compound to create a surface suitable for final decoration. External corners are normally reinforced with either a metal or plastic corner bead which in turn is covered with joint compound. Exposed edges are covered with metal or plastic trim. The result is a smooth, unbroken surface ready for final decoration of paint, textures, wallpaper tile, paneling, or other materials.

Here at Insulation Shop you can find a various types and sizes of Gypsum based boards, produced by leading manufacturers, such as British Gypsum, Fermacell.

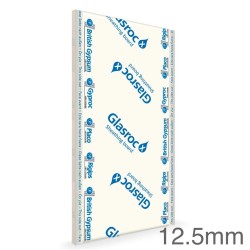

Glasroc H Tilebacker - a water resistant, Class A1 and Class 0, non-combustible glass reinforced gypsum board, suitable as a tile backing board in areas subject to high levels of moisture.

Glasroc MultiBoard is a highly versatile, Class 0, non-combustible glass reinforced gypsum board manufactured by a unique continuous process, developed and patented by British Gypsum.

Glasroc F Firecase is a highly versatile, Class 0, non-combustible glass reinforced gypsum board.

British Gypsum Rigidur H is the outer board component in British Gypsum's GypWall EXTREME system with increased rigidity and durability.

Gyproc Moisture Resistant (MR) Board is Gypsum plasterboard with water repellent additives in the core and paper liners that consists of an aerated gypsum core with glass fibre, water repellent and other additives encased in and firmly bonded to strong paper liners.

Gyproc CoreBoard is a 19mm thick version of Gyproc FireLine Moisture Resistant (MR) board that consists of an aerated gypsum core with glass fibre, water repellent and other additives encased in, and firmly bonded to strong paper liners.

Gyproc Plank Plasterboard is a 19mm board, consisting of aerated gypsum core bonded to ivory or brown face paper liners, available in both tapered and square edge versions.

Gyproc Thermaline Basic Insulated Plasterboard is a highly efficient board consisting of carefully designed components, offering not only insulation, but also fire resistance.

Gyproc Thermaline PIR Insulated Plasterboard is a highly efficient board consisting of carefully designed components, offering not only insulation, but also vapour control and fire resistance.

Fermacell is a high performance multi-purpose building board that combines the properties of solid blockwork with the speed and flexibility of conventional drywall techniques.