Fire Resistance of External Wall Insulation Systems

How to Choose the Most Adequate EWI Solution?

When choosing the most suitable insulation material, many things come to mind, since there are a lot of different aspects to take into account. The choice in material will ultimately depend on its purpose, the characteristics of the environment it is installed in and the overall result one is expecting to achieve with insulation. Sometimes the price of the material will be the prevailing criterion (especially in massive projects that are usually quite expensive), in other cases it will be its quality, strength and robustness, while sometimes some additional features may be the ones imposing the final decision. This especially goes for some industrial or commercial environments where there are a few additional hazards and potential risks that must be included in the equation, such as fire risks why you must make sure that the material or an insulation system you have chosen will offer required level of fire resistance. This is especially important when installing an entire insulation system, since deficiency of a single component can jeopardize the efficiency and function of the entire construction. This is why we shall discuss the issues related to fire resistance of external wall insulation systems.

About EWI Systems

The external wall insulation might just be the thing you need, since it includes a number of carefully chosen and combined components that are especially designed to offer protection and insulation for your external wall. You will notice that these systems are a bit more expensive and somewhat more complicated to install than traditional interior wall insulation products, but also have many advantages why they are often any homeowner or professional contractor first choice.

In order of understanding how the system works, we will herewith try to briefly explain what it includes. The most important component is the very insulation material, which can some fibre based insulation (such as rock wool) or some rigid insulation board such as PIR insulation or phenolic boards. The insulation material is then bonded to the designated wall surface with some adhesive, them usually primed and finally covered with some external finish or a render of your choice (such as mineral, silicone, silicate renders etc). Please note that installing external wall insulation system includes a number of other components such as appropriate fixings, meshes, beads and profiles, designed to keep the insulation material in place or add additional protection.

Insulation Materials Fire Performance

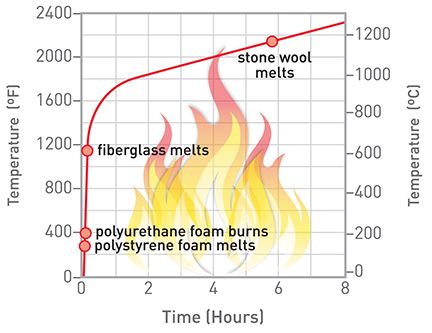

Fire performance of different insulation products and the surrounding structure, especially in complex systems that include a number of components that all have different fire resistance characteristics has been a major issue over the years. This is why the Building regulations and British standards include a number of relevant fire resistance indicators and testing methods designed to determine how building materials will react in case of a fire breaking out (such as the EPIC Fire Research Tests). The tests were developed to determine the reaction to fire that is the behaviour of different materials, singly or jointly, when exposed to fire. The other aspect of the tests should determine the fire performance of insulation and other components of the system that is the ability of the system to prevent the fire from spreading, which will depend on the loadbearing capacity of the structure, its ability to prevent the spread of flames and the ability to prevent the transmission of fire. Levels of fire resistance of different materials are set in the Approved document B of the Building Regulations, depending on the height, size and use of the building, among other criteria.

Rigid PUR and PIR boards

Rigid urethane insulated boards in external wall insulation systems are among the most commonly used materials in the UK and over Europe, and for a good reason, since they offer many advantages, including their fire performance. Although the tests have shown some loss of adhesion between the facings and the insulation core, it did not affect the structural stability of the boards. Basically, since urethane based materials are thermosetting, meaning that these will harden in case of a fire and form a char, with no flame spread through the insulation core. The boards will slowly decompose and create protective char, whereas the process stops when fire is put out. Generally, the test results have shown that, when exposed to fire, rigid urethane boards in EWI systems, maintained the integrity of the structure, there was not fire spread in the insulation core and low smoke emissions.

If you believe that these boards can be your first choice, we suggest you visit our home page and take a look at what we have to offer, such as the highly efficient Celotex SW 3000 PIR insulation board.

Polystyrene boards

Unlike the previously explained option, polystyrene boards react to fire completely differently, since the material will melt, shrink (at approximately 100º C) and burn (at approximately 180º C) when exposed to high temperatures. As a result, once the melting has begun, a void is created so the forming flame droplets can flow both in and out the external wall insulation system installed. This means that once the fire has reached the insulation, it will easily reach the insulation core and affect the speed of flame spread. Thus, this probably should not be your first choice if you are looking for insulation for industrial or commercial buildings where the risks of fire breaking out are higher, since as explained, the tests have shown that the polystyrene material will eventually melt, cause flame droplets and even cause the unsecured facings to collapse.

All the above mentioned is the reason why polystyrene boards are Euroclass F rated (no performance determined), when it comes to their fire performance and often come or are available with flame retardant. This is the case with EPS70 Jablite Polystyrene insulation board available right here at Insulation Shop.

Mineral wool slabs

Finally, another option worth mentioning is rock (mineral) wool as a part of an external wall insulation system. Depending on the density of the panels, they offer substantial protection from the fire, and are often used when the applicable regulation require more than 30 minutes fire resistance<, in high risk fire applications. Since rock wool is Euroclass A1 classified (non combustible), it will not combust when exposed to fire nor will it spread flames over the construction. Though the materials will be damaged in an event of a fire and might need replacement, the structural stability as well as the integrity of the insulation, will not be jeopardized. However, please note that although the fibres are non combustible, that may not be the case with the bonding agents used to bind the fibres, which should be taken into account when estimating the fire performance of the entire EWI system, since this may contribute to smoke emission and fire load.

If you need any advice on External Wall Insulation systems or wish to buy insulation with no fuss and save time and money, contact us via Insulation Shop phone or email address.