Dry Lining

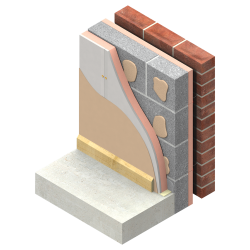

Dry lining is a construction method that uses thin plasterboard panels witch are fixed to preset metal or timber frames or to a masonry surface. Dry lining system replaced time consuming wet plaster as a material of choice for interior wall and ceiling finishes. It’s a simple and convenient solution for modern construction needs in order to save time and money but still achieve a high quality finish. Each plasterboard panel is composed of a paper liner wrapped around the inner core made of gypsum plaster, but they differ in specific components added later for use in different environment.

- Production process is environmentally friendly,

- Good moisture regulation thanks to a high quality material and tiny pores within the panel,

- Flexibility,

- Panels are easy to mount and transport, Cuts costs and reduces construction time,

- Wiring can be easily done through the hollow part of the wall with less costs.

- Dry lining guarantees space saving of up to 10%,

- Provides good thermal protection,

- Wall construction absorbs sound waves and weakens them by slowly vibrating the large panel.

- Plaster binds about 20% of crystalline water, which in a panel thickness of 12.5 mm is about 2 litres of water per square meter.

- In case of fire, the water has a self-extinguishing function.

Types of plasterboard panels

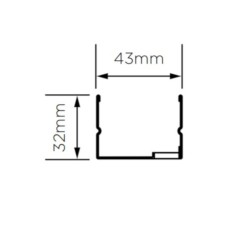

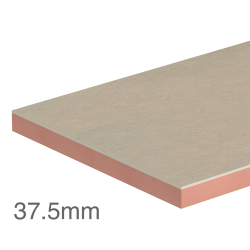

There is a wide variety of standard and high performance plasterboards, depending on their characteristics and function. Plasterboards are usually made in 60, 90 and 120 cm wide panels. They are commonly made in 240 cm lengths, though 270 cm and 300 cm length panels are also available. Plasterboards usually come in three thicknesses, 9.5 mm-used for ceilings, and 12.5 mm and 15 mm-used for walls. Insulation plasterboards (PIR) vary in insulation thickness from 25 mm to 65 mm, with 9.5mm and 12,5mm plasterboard base.

Insulation Shop London offer a full range of plasterboards to meet all dry lining requirements, including high performance boards for greater fire, moisture, vapour, sound and impact results.

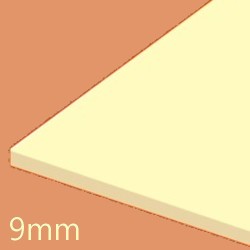

Wall board is a standard plasterboard with an ivory paper face ideally suited to receive a plaster finish or for direct decoration.

Vaporshield panel is also a standard plasterboard with addition of a metallized polyester foil laminated on the grey paper face, creating an effective vapor barrier.

Soundshield board is designed for use in areas where sound reduction is of particular importance. It’s high mass and tuned core help absorb sound energy, giving it enhanced acoustic performance.

Fireshield board offers superior fire protection. Different thickness and multiple layers of wall board provide increased fire rating based on the time a specific wall assembly can withstand a standardized fire test.

Moistureshield board is a high performance plasterboard designed for use in internal areas of high humidity and temporary external exposure. It contains an oil-based additive in the green coloured paper covering that provides moisture resistance. It is commonly used in wash-rooms and other areas expected to experience elevated levels of humidity.

Impact resistant board is a plasterboard panel offering toughness, durability and excellent load carrying capacity.

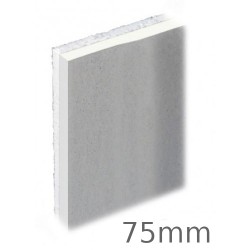

Insulated plasterboards deliver an exceptional thermal performance which is over 100% more thermally efficient than many mineral fibre products. They are suitable for roofs, walls and floors, including specific products for internal and external solid walls.

All of these products are on offer at Insulation Shop London, produced by the top branch companies like Knauf and Celotex.