Ceresit CT85 Flex - Adhesive and Base Coat for Expanded Polystyrene (EPS) Boards - 25kg

- Product Code: A1-4830

- Delivery Time: In Stock 1-2 working days

- Brand: Ceresit

- Model and Size: 25kg

- Weight: 25.00kg

4.7 out of 5 - Excellent

Ceresit CT85 Flex - Adhesive and Base Coat for Expanded Polystyrene (EPS) Boards - 25kg

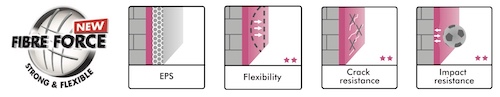

Ceresit CT85 Flex is a versatile, cementitious adhesive and base coat designed for use with expanded polystyrene (EPS) boards in external thermal insulation composite systems (ETICS). Formulated to provide exceptional adhesion and flexibility, this product plays a crucial role in the Ceresit Ceretherm system, ensuring a secure and durable bond between the insulation boards and the facade. Suitable for both adhesion and base coat applications, Ceresit CT85 Flex offers a range of benefits that make it an ideal choice for a variety of construction projects. Its composition provides enhanced flexibility, allowing the system to accommodate minor structural movements and thermal expansion without cracking or delamination. This flexibility, combined with its excellent adhesive strength, helps to create a robust and long-lasting facade that can withstand the rigours of the British climate.

Ceresit CT85 Flex also benefits from the Fibre Force Technology, a specially selected combination of fibres that strengthens the resistance of the insulation system to damage, cracks, and scratches. This added reinforcement helps to improve the overall durability and longevity of the facade, ensuring it maintains its aesthetic appeal and structural integrity over time. In addition to its superior performance characteristics, Ceresit CT85 Flex is also easy to apply, whether by trowel or spray. Its smooth, creamy consistency ensures a uniform, even coverage, while its extended open time allows for efficient and precise installation of the EPS boards. Once cured, the base coat provides an ideal substrate for the application of the final render or decorative finish, ensuring a seamless and aesthetically pleasing result. Ceresit CT85 Flex is an essential component of the Ceresit Ceretherm system, contributing to the overall thermal efficiency and durability of the building envelope. Its versatility, reliability, and enhanced reinforcement make it a popular choice among architects, contractors, and homeowners alike, who value the peace of mind that comes with a high-quality, proven insulation solution.

Assumed consumption:

- Fixing of EPS-boards: approx. 5.0 kg/m2

- Armoured layer: approx. 4.0 kg/m2

- Putty layer: approx. 1.0 kg/m2

- High adhesion to mineral substrates and EPS boards,

- Cementitious adhesive and base coat

- Designed for use with EPS boards in ETICS (External Thermal Insulation Composite Systems)

- Provides exceptional adhesion and flexibility

- Enhances the durability and resistance of the insulation system

- Features Fibre Force Technology for improved resistance to damage, cracks, and scratches

- Accommodates minor structural movements and thermal expansion without cracking or delamination

- Easy to apply by trowel or spray

- Smooth, creamy consistency for uniform coverage

- Extended open time for efficient and precise installation of EPS boards

- Provides an ideal substrate for the final render or decorative finish

- Essential component of the Ceresit Ceretherm system

- Contributes to the overall thermal efficiency and durability of the building envelope

- Suitable for a wide range of residential and commercial construction projects

- Possibility of machine application

- For fixing Expanded Polystyrene (EPS) boards for applying a thin reinforced layer for external thermal insulation of buildings by means of light wet method.

Click here to find Why Choose Ceresit Insulated Renders

How to use

- Ensure the substrate (e.g., wall surface) is clean, dry, and free from any loose particles or contaminants.

- If necessary, apply a primer coat to the substrate as recommended by the manufacturer.

Adhesive Application:

- Mix the Ceresit CT85 Flex adhesive thoroughly with clean water until a smooth, lump-free consistency is achieved.

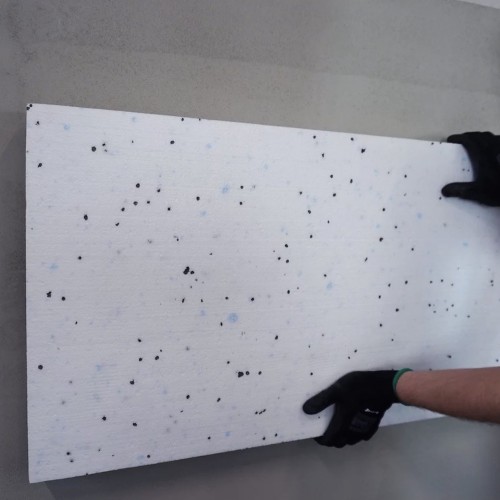

- Apply the adhesive to the back of the EPS board using a notched trowel, creating a uniform layer.

- Immediately press the EPS board firmly onto the prepared substrate, ensuring full contact.

- Secure the board in place and maintain pressure until the adhesive has set.

Base Coat Application:

- Once the adhesive has cured, apply a layer of Ceresit CT85 Flex over the surface of the EPS boards using a stainless steel trowel.

- Embed a reinforcing mesh (e.g., Ceresit CT327 Reinforcing Mesh) into the wet base coat, ensuring proper overlapping and coverage.

- Smooth the surface with the trowel to create a uniform, even finish.

Drying and Curing:

- Allow the base coat to dry for at least 24 hours before applying any subsequent coatings or finishes.

- Ensure adequate ventilation and avoid direct sunlight or strong winds during the drying period.

- The base coat will fully cure within 2-3 days, depending on environmental conditions.

CERTIFICATION

- BBA Certificate No. 14/5142

- Complies with the requirements of ETAG 004 (Guideline for European Technical Approval of External Thermal Insulation Composite Systems with Rendering)

- Approved for use in Ceresit Ceretherm systems for the thermal insulation of external walls (ETICS)