Ceresit CT83 Strong Fix Adhesive Mortar for EPS and XPS Boards

- Product Code: A1-2342

- Delivery Time: 7 - 10 days

- Brand: Ceresit

- Model and Size: CT83 - 25kg

- Weight: 25.00kg

4.7 out of 5 - Excellent

Ceresit CT83 Strong Fix Adhesive Mortar for EPS and XPS Boards

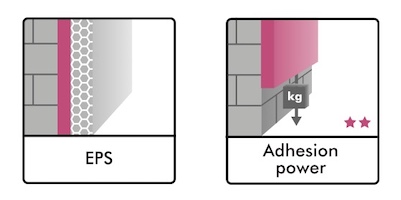

Ceresit CT83 Strong Fix Adhesive Mortar is a high-performance, cement-based adhesive specifically designed for bonding EPS (Expanded Polystyrene) and XPS (Extruded Polystyrene) insulation boards. This product is suitable for both interior and exterior applications, providing a robust and durable bond even in challenging weather conditions. Ceresit CT83 Strong Fix is made from a cement and lime mixture with mineral fillers and modifiers, ensuring a strong and durable bond for your construction or renovation project. It can be used within Ceresit ETICS (External Thermal Insulation Composite Systems) with a light-wet method, ensuring a secure and efficient bond for your insulation system.

Assumed consumption: approx. 5.0 kg/m2

CHARACTERISTICS

- Exceptional adhesion

- High strength

- Weather-resistant

- Easy to use

- Environmentally friendly

- Can be used within Ceresit ETICS (External Thermal Insulation Composite Systems) with a light-wet method

- Made from a cement and lime mixture with mineral fillers and modifiers, ensuring a strong and durable bond for your construction or renovation project.

- Possibility of machine application

APPLICATION

- For fixing EPS and XPS boards for external thermal insulation of buildings

Click here to find Why Choose Ceresit Insulated Renders

- Ensure that the surface to be bonded is clean, dry, and free from any contaminants such as dust, oil, or grease. Remove any old adhesive or loose material from the surface.

- Mix the contents of the Ceresit CT83 Strong Fix Adhesive Mortar bag with water according to the manufacturer's instructions. Typically, this involves adding the recommended amount of water to a clean container and gradually adding the powder while mixing until a smooth, lump-free consistency is achieved.

- Apply the mixed adhesive mortar to the surface using a notched trowel, ensuring an even layer of adhesive is applied. The recommended thickness of the adhesive layer depends on the type and thickness of the insulation board being used.

- Press the insulation board firmly onto the adhesive mortar, ensuring good contact between the board and the adhesive. Use a roller or a similar tool to remove any air pockets and ensure a uniform bond.

- Allow the adhesive to cure according to the manufacturer's instructions. The recommended curing time depends on various factors, such as temperature and humidity.

CERTIFICATION

- BBA Certificate No. 14/5142

- European Technical Approval (ETA) 13/0086,

- European Certificate of Conformity No. 1488-CPR-0407/Z