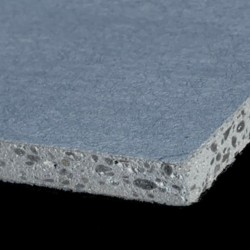

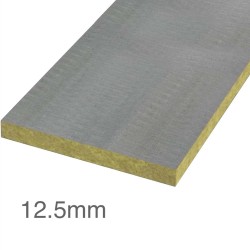

Render Carrier Boards

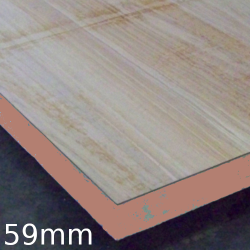

The great value of cement boards is that they don't rot, warp, grow mould, or deteriorate, when subjected to water and harsh changes of weather. These boards are normally applied to treated timber frame or a lightweight steel frame structures, where a thin coat render systems to be applied to. These boards are easier to cut, as they can be scored and snapped. They provide good impact resistance and offer class A1 non-combustibility. They will also provide certain amount of weather protection before they are rendered.

Render carrier boards provide a solid, durable surface that can withstand extreme weathering effects of wind, rain and snow, while providing an impact-resistant barrier. Usually render carrier boards dont rot or swell when they come into contact with water, and can be stored outside.

- Faster construction times,

- More return on investment,

- Low maintenance,

- Smooth surface,

- Easy to work with,

- High fire, sound and thermal performance,

- Good water repellence properties,

- Resistant to mould and mildew.

- Ideal for bathrooms, wet-rooms and kitchens,

- Perfect for areas with high humidity, non-combustible,

- Will not rot or warp

- As substrate for wood frame and metal frame external vertical and horizontal structures.

- As an exterior siding.

- As an underlayment for flooring.

- Use gloves, goggles and fine toothed saw,

- Make a dry run. Lay out boards, but do not affix to the surface yet.

- Mark partial boards by drawing cut lines on the surface of the cement board with a carpenter's pencil.

- Where the board must go around irregular obstructions, such as plumbing pipes, toilets etc., draw a template on contractor's paper, cut out the template with scissors, then transfer that pattern to the backer board with pencil. On regular obstructions such as windows, doors etc, measure and cut the boards to size and number them.

- Fix the planned out boards to the surface with screws, and where needed use thinset mortar. Screw heads should be slightly below the cement board surface.

- Cover seams with fibreglass seam tape.

- Fill in and smooth with mortar. Let dry.

- Depending on the application, lay tiles or plaster.

Here at insulationshop.co you'd find you can find find various types and sizes cement based backer boards, render carrier boards, sheathing boards from well known manufacturers such as Euroform, James Hardie, Knauf, RCM.

Versa Rendaboard is a solid white in colour direct render base board, carefully designed for direct render applications, with textured face to one side and compatibility with a vast number of polymeric coating systems.

Versapanel cement bonded particle board is an innovative building material especially designed to meet the set requirements in regard to moisture tolerance and fire resistance, durability, safety and flexibility.

Hardiebacker cement floor board is backboard used as an ideal substrate for vinyl, natural stone and ceramic tiles.

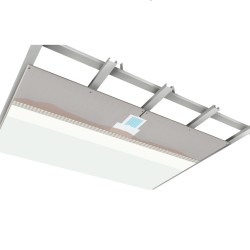

Knauf Aquapanel Irior Cement Board is an ideal substrate for directly applied render finishes and can be used for exterior walls in ventilated systems,exterior ceilings.

Renderflex is a cellulose/fibre cement based render carrier board, primarily used as base board for polymer modified render systems which do not include insulation added to the board before rendering.