British Gypsum Thistle UniFinish Plaster- 25kg

British Gypsum Thistle UniFinish Plaster- 25kg

- Product Code: A1-1888

- Delivery Time: Out Of Stock

- Brand: British Gypsum (Tech. support: 01159456123)

- Model and Size: 25kg

- Weight: 25.00kg

Our ratings on 22-04-2025:

4.7 out of 5 - Excellent

4.8 out of 5

British Gypsum Thistle UniFinish Plaster- 25kg

Weight: 25kg

Thistle UniFinish is a gypsum finish plaster specially formulated for re-skimming over a wide range of backgrounds with no need for pre-treatment with PVA. It provides a smooth, inert, high quality surface to internal walls and ceilings, and a durable base for the application of decorative finishes. Thistle UniFinish is a retarded hemihydrate, pre-mixed gypsum plaster, requiring only the addition of clean water to prepare it for use. Apply with firm pressure, build out to 2mm thickness in two applications and trowel to a smooth matt finish as the plaster progressively hardens through setting or by loss of water into the background.

Gypsum plasters provide good fire protection due to the unique behaviour of gypsum in fire. Materials adjacent to the unexposed side will not exceed 100°C – below the temperature at which most materials will ignite and far below the critical temperatures for structural components. Once the gypsum layer is fully calcined, the residue acts as an insulating layer while it remains intact.

Most backgrounds encountered in re-skimming jobs will need no pre-treatment before using Thistle UniFinish,

- Most paints, including matt, silk, vinyl, eggshell emulsions, kitchen/bathroom paint,

- Walls stripped of wallpaper (with minimal wallpaper adhesive remaining),

- Painted texture compounds,

- Undercoat plaster, except if very high suction (some lime-based or sand/cement backgrounds),

- Skim finish plaster

- Tile adhesive

Unsuitable backgrounds include:

- Unpainted texture compounds – these can soften significantly when wetted, leading to adhesion failure

- Self-cleaning or anti-graffiti paints – these are often designed to not fully harden, or to have a deliberately water-repellent or weak surface layer so that materials that stick to them are removed easily, so they are not suitable for plastering

- Surfaces where there is flaking or delamination between layers, and poorly bonded, friable or dusty surfaces – there is a high risk of failure unless such materials are removed

- Bags should be stored dry, as absorption of water shortens the setting time, causes set lumps to form in the bags and may reduce the strength of the set plasterwork,

- Thistle plasters should be mixed by adding to clean water in clean mixing equipment. Contamination from previous mixes adversely affects the setting time and the strength. Fresh contamination has more effect than old, so equipment should be washed just after mixing rather than just before,

- Apply in 2 coats , each coat at a minimum of 1mm thickness,

- For the best surface finish results use a clean, damp trowel,

- Avoid polishing and aim for a matt finish,

- Gypsum-based plasterwork must always be thoroughly dry before decorating, although a coat of permeable paint can be applied in the interim.

- Tiles up to 20kg/m2 can be applied directly to the Thistle Browning, except where the system includes a bonding agent.

- ISO 9001:2008 Quality Management System,

- ISO 14001:2004 Environmental Management System,

- BES 6001:Issue 2 Responsible Sourcing of Construction Products,

- BS OHSAS 18001:2007 Occupational Health and Safety Management

Brand: British Gypsum

Model and Size: PIR MR - 38mm

Delivery Time: 1 - 5 working days

38mm Gyproc Thermaline PIR MR Insulated Plasterboard consists of a 12.5mm Gyproc Moisture Resistant Board factory bonded to a 25.5mm rigid polyisocyanurate foam (PIR) with a multi-layer Kraft/aluminium facer on both sides of the insulation board and conforms to BS EN 13950. ..

Guide Price: £103.05

£123.66 inc VAT

Brand: British Gypsum

Model and Size: GA6 - 2.4 m

Delivery Time: 2 - 4 days

British Gypsum Gypframe GA6 2.4 m Splayed Angle is a specially designed product which provides additional support, strength, and protection to ceiling, wall and encasement framing constructions.The product can be used in vari..

£120.95

£145.14 inc VAT

Brand: British Gypsum

Model and Size: 2000x1200mm - 2.40m2

Delivery Time: 1 - 2 days

20mm Glassroc F Firecase is a highly versatile, Class 0, non-combustible glass reinforced gypsum board. The non-combustibility of gypsum and the reinforcement of glass fibre combine to produce a strong and resilient product, which has resistance to sag and offers excellent fire protection. It consis..

Guide Price: £70.21

£84.25 inc VAT

Brand: British Gypsum

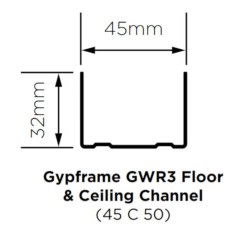

Model and Size: GWR3 - 2.4m

Delivery Time: 3 - 5 days

British Gypsum Gypwall Rapid GWR3 Floor and Ceiling Channel is especially designed to be used with the GypWall RAPID dB PLUS internal wall system incorporating Gyproc SoundBloc RAPID linings, providing not only acoustic insulation but also impact and fire resistance, in accordanc..

£65.18

£78.22 inc VAT

Brand: British Gypsum

Model and Size: Basic - 40mm

Delivery Time: 2 - 3 working days

40mm Gyproc Thermaline Basic is a 9.5mm Gyproc wall board factory-bonded to a 30.5mm expanded polystyrene insulant that is both CFC and HCFC-free. The Gyproc board consists of an aerated gypsum core encased in, and firmly bonded to, strong paper liners. The expanded polystyrene insulant i..

£41.61

£49.93 inc VAT

Brand: British Gypsum

Model and Size: 1400kg - pallet of 56

Delivery Time: Out Of Stock

Thistle Board Finish is a gypsum finish plaster for use on low to medium suction backgrounds. It provides a smooth, inert, high-quality surface for internal walls and ceilings, serving as a durable base for the application of decorative finishes. Thistle Board Finish is a retarded hemihydrate, pre-m..

Guide Price: £481.89

£578.27 inc VAT