Acoustic Insulation and Soundproofing

According to Part E of the Building Regulations implemented by the government legislation in 2004 all newly build houses must be fitted with acoustic insulation to improve sound performance of wall partitions, separating floors, and ceilings.

Sound pollution is commonly recognised as a household issue in all types of building construction but unless special care is taken by the builder to provide sufficient acoustic insulation for the walls, floors and ceilings, the homeowner is likely to hear allot of unwanted sounds from footstep noise in the room above to movie playing on the home theatre down the hall.

Sound insulation is required to prevent noise (unwanted sound) being transmitted either from room to room within a building or from external sources. The transmission of noise within a building is by two main routes:

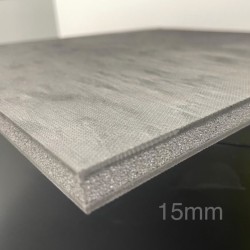

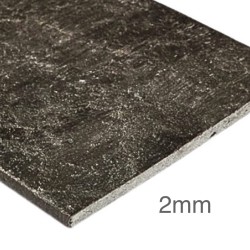

- Airborne Noise – as the name suggests generally this is noise transmission through the air. It is complicated however in that this noise may generate vibrations in walls, floors and ceilings which then transmit the airborne sound to other parts of the building. The use of absorbent layers and/or the addition of mass to the structure will help reduce airborne noise transmission.

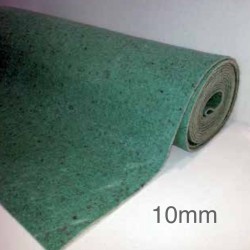

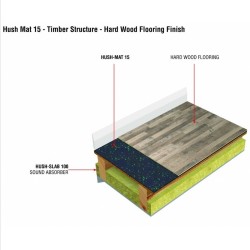

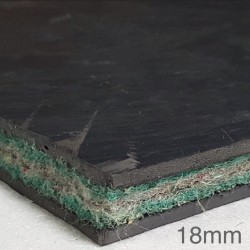

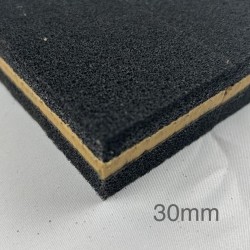

- Impact Noise – the most common instance of impact noise is footsteps on floors in blocks of flats and similar buildings. The use of resilient and absorbent layers and/or the addition of mass to the structure will help reduce impact noise transmission.

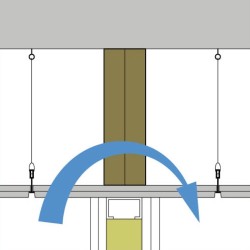

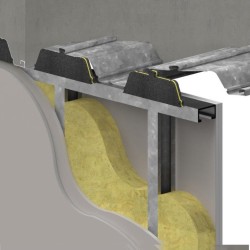

- buildings are also prone to flanking transmission where both airborne and impact sound energy may be transmitted indirectly through the structure (for example at the junctions of floors and walls). Great care in detailing and the isolation of elements is required to minimize flanking transmission.

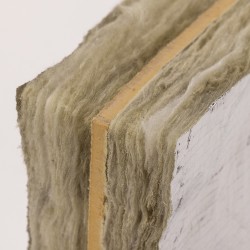

Air gaps passing through the structure offer a direct route for sound transmission. Great care should be taken to seal joints between and around elements and around service penetrations. Sound-dampening acoustic batt insulation installed into partitions during construction is a very good choice for reducing sound pollution. It is highly recommended that the insulation fits snugly into place, and that it fills the wall cavity. Acoustic insulation should be carefully cut to fit around electrical boxes and pipes eliminating any gaps or holes that could easily allow sound to flow through.

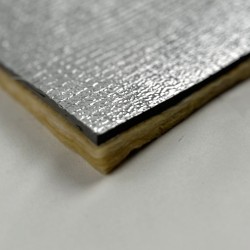

Sound waves are reflected when they hit a hard surface. Acoustic insulation is made from porous materials of varying density and composition to convert the sound energy into heat within the open pores and absorb part of the reflected sound. In order to maintain the best absorption values the air channels should be open to the surface so that sound waves can propagate into the material. Pores in acoustic insulation should not be sealed by paint or any other coverings. Any protective shielding for the acoustic insulation should generally be perforated to maintain soundproofing values. Acoustic insulation should also be kept dry during storage to maintain its soundproofing capabilities.

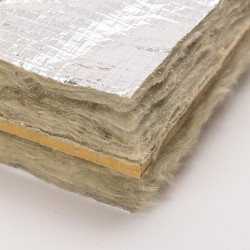

Using mineral wool as a sound absorbent layer in partitions and floors significantly improves their acoustic performance, whilst only adding minimally to the overall mass of the structure. In partitions glass mineral wool complements the plasterboard by absorbing airborne sound in the cavity and reducing reverberation, It Is particularly effective at preventing the hollow sound that can occur in partitions with unfilled cavities.

The ability of an acoustic insulation material to absorb sound is usually provided in the form of an absorption coefficient. The absorption coefficient is defined as the ratio of sound energy absorbed by a given surface, to the sound energy incident upon that surface. The absorption coefficient can vary from 0 to 1. If for example the absorption coefficient is 0.9, then 90% of the sound energy will be absorbed by that material. Most porous absorbers are more efficient at high frequencies, while improving the materials thickness, or mass, can increase low frequency absorption.

Sound Transmission Class (STC) is a scale used to rate partitions like walls or floors on how well they reduce sound or noise levels. The rating directly reflects the number of decibels (dB) a partition reduces. Normal conversation is about 60 dB. A standard interior wall with 3/8" gypsum board has an STC of about 35. This means if someone were speaking at normal level in the next room, you would hear about 25 dB of noise, or just over a whisper.

Insulationshop.co offers wide range of acoustic insulation products from manufacturers: BRITISH GYPSUM, CMS DANSKIN, CELLECTA, EUROFORM, ISOMASS, ISOVER, JCW, KARMA, KNAUF, MARMOX, ROCKWOOL, SUPERGLASS, THERMAFLEECE, URSA and XTRATHERM are suitable for soundproofing all kinds of partitions. For more information about particular product please see product description.