75mm Unilin Thin-R Hyfloor XT/HYF Under Floor PIR Insulation Board - Pack of 4

- Product Code: A1-4962

- Delivery Time: 1-3 working days

- Brand: Unilin (prev. Xtratherm)

- Model and Size: 1200x2400mm - 11.52m2

4.7 out of 5 - Excellent

75mm Unilin Thin-R Hyfloor XT/HYF Under Floor PIR Insulation Board - Pack of 4

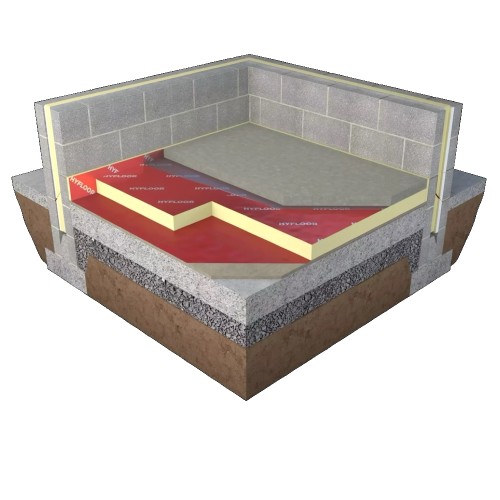

75mm Unilin Thin-R Hyfloor XT/HYF is a high performance floor Insulation board with superior thickness to performance ratio allowing the lower targets required under the new Building Regulations to be achieved with minimum thicknesses. Unilin Thin-R Hyfloor XT/HYF is a high performance foil faced Polyisocyanurate (PIR) insulation with a certified thermal conductivity as low as 0.022W/mK. Manufactured to strict EN 13165 standards, the closed cell structure and gas tight facings provides excellent thermal performance and moisture resistance. It has an engineered jointing to provide improved continuity and unparalleled thermal bridging performance.

- High Thermal Performance,

- Easy to Install,

- T&G jointing on all four edges,

- Suitable for underfloor heating,

- Suitable for new build and refurbishment,

- Achieves Zero Carbon Standards,

- Reduces Thermal Bridging,

- Certified Lambda Value as low as 0.022 W/mK,

- Closed cell structure – moisture resistant

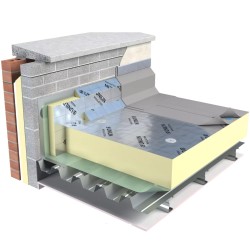

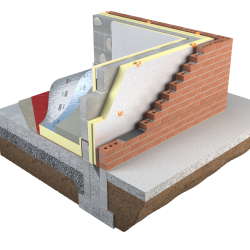

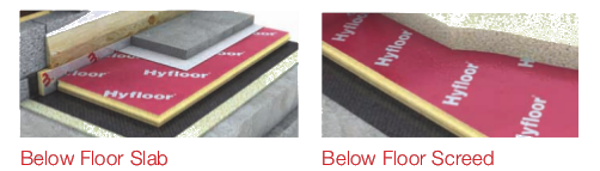

Suitable for new build and refurbishment. Above floor slabs and below floor screed.

Unilin Thin-R Hyfloor XT/HYF boards should be stored off the ground, on a clean, flat surface and must be stored under cover. The polythene wrapping is not considered adequate protection for outside exposure.

- Lay the hardcore in layers (150mm to 225mm). Each layer should be well compacted, with the surface blinded with quarry dust or sand to provide suitable surface for laying DPM.

- A damp proof membrane e.g. 1200 gauge polythene or radon barrier should be laid over blinding with joints taped to prevent passage of ground moisture, it should be carried up the wall until it meets and seals with the DPC.

- Hyfloor should be laid with closely butted T&G joints, laid staggered with a break bonded pattern and fitted tightly at edges and around any service penetrations.

- Place a layer of polythene over any under floor insulation to act as a separating layer.

- Ensure that the floor slab or beams onto which the insulation is being laid is level, a blinding of sand may be required.

- The concrete floor over which the insulation is to be laid should be left as long as possible to maximise drying out, in accordance with BS8203: 1996 Section 3.1.2.

- The minimum thickness of sand and cement screed is 65mm for domestic construction and 75mm for most other buildings.