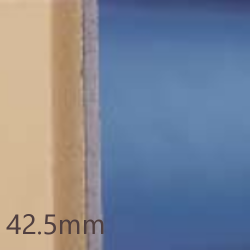

42.5mm Knauf Polyfoam Linerboard - 30mm Extruded Polystyrene (XPS) and 12.5mm Plasterboard

42.5mm Knauf Polyfoam Linerboard - 30mm Extruded Polystyrene (XPS) and 12.5mm Plasterboard

- Product Code: A1-2143

- Delivery Time: 5 - 7 days

- Brand: Knauf (Tech. support: 08000304135)

- Model and Size: 1200x2400mm - 2.88m2

- Weight: 26.60kg

Product discontinued.

Click Get Best Price to request a quotation and we will recommended an equivalent product.

Our ratings on 23-04-2025:

4.7 out of 5 - Excellent

4.8 out of 5

42.5mm Knauf Polyfoam Linerboard - 30mm Extruded Polystyrene (XPS) + 12.5mm Plasterboard

Width: 1200mm

Length: 2400mm

Density: 217kg/m3

Weight/m2: 9.23kg

Weight: 26.6kg

Thermal Conductivity: 0.030W/mK

R-Value: 1m2K/W

42.5mm Polyfoam Linerboard is a high performance, tapered edge, rigid composite internal insulated plasterboard with 30mm extruded polystyrene (XPS) bonded to 12.5mm plasterboard. It allows the thermal insulation and lining of internal, semi-exposed and exposed walls in one simple operation. The rigidity of the Polyfoam liner offers an excellent support to the finished internal lining and has high impact resistance. helping to prolong its service life.

CHARACTERISTICS

- Simple to install,

- Easy to handle and non-irritant, no special protective clothing is required to install them.

- Easily cut with a sharp knife, scored and snapped open to get a clean cut.

- Can be fixed with adhesives or mechanically fixed or in a combination of both,

- Low moisture absorption,

- Can be installed on damp walls and in damp cavities,

- High thermal performance,

- Stability in the long term usage,

- High resistance to impact,

- High quality facing material,

- Plasterboard offers excellent fire performance and the Polyfoam XPS insulation contains a flame retardant to inhibit localised ignition.

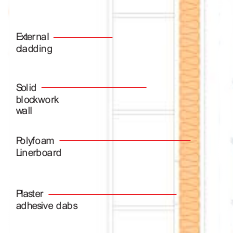

APPLICATION

- Internal insulation and lining of masonry walls in new build or refurbishment,

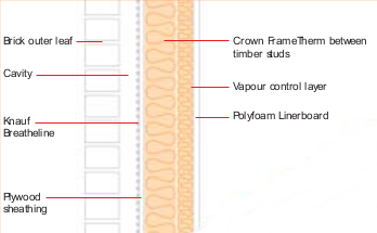

- Internal insulation and lining of metal frame and timber frame walls in new build or refurbishment,

- Housing,

- Offices,

- Schools,

- Hospitals,

- Retail,

- Public buildings

Precautions

- The boards should not be left exposed to prolonged sunlight as this will result in surface degradation.

- If stored outside for extended periods, they should be covered with opaque or light coloured sheeting.

- Do not store the boards close to open flame or other ignition source.

- Avoid volatile compounds and chemicals such as solvents in contact with the boards.

- The surface be lined should be clean and dry with all wall paper and loose plaster or other material removed.

- Holes for services, other fixtures etc should be cut before fixing the board.

- Boards can be either sawn or cut with a sharp knife.

- Linerboard can be fixed to the substrate with adhesive (dabs or around the perimeter) and mechanically fixed or both the methods.

- With both adhesive and dab fixing methods, two mechanical fixings are required at the top of each board, 25mm in from the edge. They should penetrate at least 35mm into a solid substrate.

- When fixing to a metal or a timber frame, the studs of the timber frame should be at least 50mm wide and placed at 600mm maximum centres, with additional framing to provide support at all board edges.

- On a timber frame, the Linerboard is secured by nailing at 150mm maximum centres, at least 12mm in from the board edge. The fixings should be long enough to penetrate at least 25mm into the timber.

- On a metal frame, the Linerboard is secured using self tapping screws at 200mm maximum centres, located at least 12mm in from the board edge. The screws should be long enough to penetrate at least 15mm into the frame.

- Standard plasterboard jointing techniques are used to finish the board ready for direct application of paint or wallpaper.

Note: This product can be supplied with different types of plasterboards, such as Cement based boards, Gypsum boards, Calcium Silicate boards, OSB, Plywood etc.

Brand: Knauf

Model and Size: 1200x2400 - 172.8m2

Delivery Time: 2 - 3 working days

15mm Knauf Wallboard is a high-quality gypsum-based plasterboard commonly used for interior wall and ceiling applications. It consists of a solid gypsum core encased in a durable paper lining on both sides. The plasterboard provides a smooth, flat surface that is easy to decorate with paint, wallpap..

£800.03

£960.04 inc VAT

Brand: Knauf

Model and Size: 1200mm x 1800mm - 2.16m2

Delivery Time: 5 - 10 Working Days

20mm Knauf Fireboard is a fleece-lined high performance square-edge plasterboard that provides up to two hours of fire protection in structural steel encasement. It is also ideal for use as fillets in deflection head details (an elastic polyurethane foam with intumescent firestop additives acts as a..

Guide Price: £50.47

£60.56 inc VAT

Brand: Knauf

Model and Size: 1200x2400 - 2.88m2

Delivery Time: 1 - 2 days

15mm Knauf Fire Panel Plasterboard is a high-performance gypsum-based board designed to provide enhanced fire resistance. It is a popular choice for use in walls and ceilings where fire safety is a key consideration. Knauf Fire Panel features a core composed of a specially formulated gypsum compound..

£23.51

£28.21 inc VAT

Brand: Knauf

Model and Size: 625x2400mm - 1.50m2

Delivery Time: 1 - 2 days

12.5mm Knauf Silentboard is a unique patented plasterboard that is ideal to use in drywall partitions which outperform the sound reduction of traditional plasterboard across a wider range of sound frequencies. Knauf Silentboard is used in in cinemas, entertainment complexes and other buildings where..

Brand: Knauf

Model and Size: 1250x2000mm - 2.50m2

Delivery Time: 4 - 5 weeks

10mm Knauf Thermoboard is a high performance plasterboard designed for use in chilled ceiling applications, and with wall and ceiling heating applications. The low thermal resistance of the board allows for improvements of up to 20% in the operating efficiency of cooling and heating systems. It has ..

Brand: Knauf

Model and Size: 1200x2400mm - 2.88m2

Delivery Time: 5 - 7 days

42.5mm Polyfoam Linerboard is a high performance, tapered edge, rigid composite internal insulated plasterboard with 30mm extruded polystyrene (XPS) bonded to 12.5mm plasterboard. It allows the thermal insulation and lining of internal, semi-exposed and exposed walls in one simple operation.&nb..