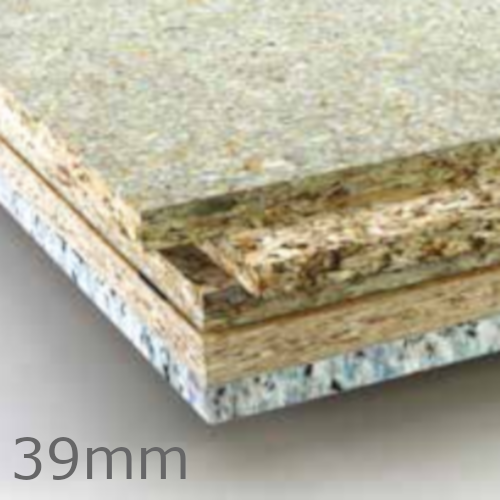

39mm Karma Visco 600 Acoustic Overlay Board

- Product Code: A1-2549

- Delivery Time: 2 - 3 working days

- Brand: CMS Danskin Acoustics (Tech. support: : 01925577711)

- Model and Size: 2400x600mm - 1.44m2

- Weight: 29.52kg

4.7 out of 5 - Excellent

39mm Karma Visco 600 Acoustic Overlay Board

39mm Karma Visco 600 is an acoustic overlay board designed to reduce the effect of impact and airborne sound passing through existing timber floors. Karma Visco 400 can be laid direct to joists and can span between joists at a maximum of 400mm centres. The boards are used for conversion projects where there is a need to provide a new structural deck with acoustic properties over timber joists. They can also be used as a high performance overlay board above an existing deck. All products are supplied factory bonded.

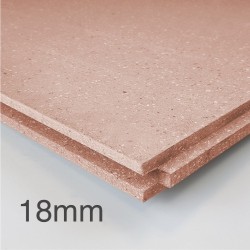

The board comprises two layers of moisture resistant chipboard, separated by Visco elastic sound damping strips with an acoustic felt resilient layer on the underside. This cushioning resilient layer on the underside further reduces impact sound transmission.

- Excellent impact and airborne sound performance,

- Used for 600mm joist centres,

- Can be installed directly to joists,

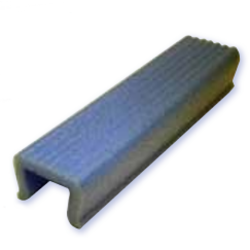

- T&G edge profile for ease of installation,

- Acoustic felt contours over minor irregularities,

- Will not add to existing fire hazard when properly installed,

- Can be used with most floor finishes,

- Lightweight non load bearing partitions can be supported on top of Karma Visco 600.

- Refurbishment projects where a new structural deck is required above joists and a new acoustic ceiling is to be fitted,

- Where height restrictions exist but reliable performance is still required.

- Joist surfaces should be level prior to the start of installation. Place Karma isolation tape between Karma Visco overlay boards and perimeter walls during installation. This will reduce flanking sound transmission.

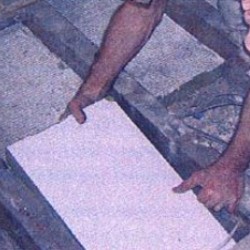

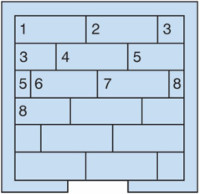

- Lay Karma Visco overlay boards as shown in the illustration with the grooved edges or cut edges facing the perimeter walls. Use the off cut from the final panel in the first row to commence the next row. Do not start a row with an off cut less that 250mm long. Lay panels in a brick bonded fashion.

- While laying boards apply a liberal amount of PU D5 adhesive to the grooves of the T&G joint and tightly butt the boards together. Wipe off excess adhesive with a damp cloth. Avoid walking on the boards until the adhesive has dried.

Note: To prevent swelling or twisting ensure the boards are kept away from water and high humidity. If boards are affected by water they should be replaced. Boards should be kept inside, under cover and in dry conditions at all times. They should be stacked flat on a level surface and should be located into the environment in which they are to be fixed at least 24 hours prior to fixing.