28mm Karma Acoustic Overlay 28 Chipboard

Guide Price

28mm Karma Acoustic Overlay 28 Chipboard

Guide Price: £32.70 (£39.24 inc VAT)

Price per m2: £22.71/m2 (£27.25 inc VAT)

To add to cart change quantity to minimum of 70. If you need less, ask for a price or add to a quote list.

- Product Code: A1-2473

- Delivery Time: 1 - 2 days

- Brand: CMS Danskin Acoustics (Tech. support: : 01925577711)

- Model and Size: 2400x600mm - 1.44m2 28mm

- Weight: 20.16kg

Our ratings on 24-04-2025:

4.7 out of 5 - Excellent

4.8 out of 5

28mm Karma Acoustic Overlay 28 Chipboard

Width: 600mm

Length: 2400mm

Sheet Coverage: 1.44m2

Density: 500kg/m3

Weight/m2: 14kg

Weight: 20.16kg

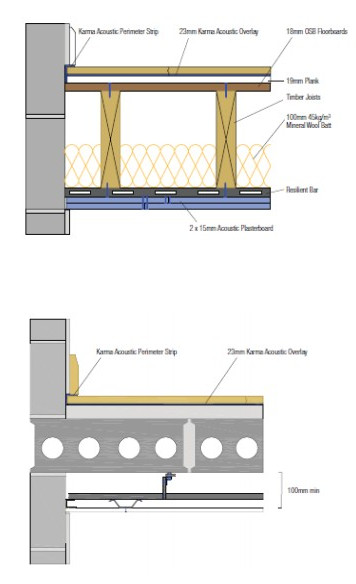

28mm Karma Acoustic Overlay 28 is a high performance acoustic floor panel with an exceptionally high sound reduction performance to height ratio. The combination of P5 chipboard and cross linked polyolefin foam make the overlay board a complete sound proofing solution, tackling both impact and airborne noise. It is used on an existing floor, new ply or chipboard floor or directly to concrete/screed floors making it an ideal product for refurbishment and new build projects. Lightweight non load bearing partitions can be supported on top of Karma Overlay 28 boards.

CHARACTERISTICS

- Cost-effective solution,

- Quick & Easy to install, offering savings labour,

- Excellent impact and airborne sound performance,

- Minimal height increase,

- Can be used with any floor finish,

- Can be used on existing subfloors or concrete/screed floors,

- Non load bearing partitions can be built off the finished floor surface,

- Eliminates the requirement for a damp proof membrane,

- Fire rating of top layer Class 0 surface spread of flame to BS 476,

- GWP <5 Global Warming Potential of resilient layer,

- Product made recycled or recyclable materials.

APPLICATION

- New build apartments, hotels, student accommodation and houses with timber joist floors,

- Refurbishment projects where height restrictions exist but reliable performance is still required

INSTALLATION

- The boards should be located into the environment in which they are to be fixed at least 24 hours prior to fixing.

- The subfloor evenness tolerances must not exceed +/- 2mm per 2 metre run.

- The base floor must also be clean and completely dried out.

- The floor should be clear of pipes and other obstacles.

- Place Karma 5mm x 100mm wide flanking strip between the panels and perimeter walls and existing door frames during installation to reduce flanking sound transmission.

- Lay boards with the grooved edges or cut edges facing the perimeter walls.

- Use the off cut from the final panel in the first row to commence the next row.

- Do not start a row with an off cut less that 250mm long.

- Lay panels in a brick bonded fashion.

- While laying boards apply a liberal amount of Karma PU adhesive to the grooves of the T&G joint and tightly butt the boards together.

- Wipe off excess adhesive with a damp cloth.

- Avoid walking on the boards until the adhesive has dried.

Brand: CMS Danskin Acoustics

Model and Size: 1.15m x 13m - 14.95m2

Delivery Time: 3 - 5 days

Regupol E48 is a high performance recycled tyre crumb acoustic flooring material used for under screed. It is designed to isolate screeds from the main structure of the building reducing the impact energy generated by general footfall. Regupol E48 acoustic flooring material is used under all types o..

Guide Price: £258.36

£310.03 inc VAT

Brand: CMS Danskin Acoustics

Model and Size: 100mm - 15m roll

Delivery Time: 3 - 5 days

100mm Regupol Acoustic Isolating Strips are designed to isolate noise and vibrations at source, a very simple and effective way to reduce structure borne noise. 15m rolls.CHARACTERISTICSA rubber crumb productCapable of withstanding loads up to and including 0.8N/mm2 with low frequency performance ac..

Guide Price: £36.16

£43.39 inc VAT

Brand: CMS Danskin Acoustics

Model and Size: 1200mm x 5m - 6m2

Delivery Time: 2 - 3 working days

52mm Karma Acoustic Blanket is an innovative acoustic quilt consists of an acoustic barrier membrane sandwiched between two layers of 25mm mineral wool for maximum effectiveness. This innovative acoustic quilt can be used in a wide range of applications. Karma Acoustic Blanket is extremely versatile..

Brand: CMS Danskin Acoustics

Model and Size: 1200x600mm - 0.72m2

Delivery Time: 5 - 7 days

Karma Acoustic MassPanel is a high performance acoustic floor panel with an exceptional performance to height ratio. Comprising an 18mm tongued and grooved cement bonded particle board laminated to a 12mm woodfibre resilient layer, Karma Acoustic MassPanel provides excellent impact and airborne..

Brand: CMS Danskin Acoustics

Model and Size: 1.25x10m - 12.50m2

Delivery Time: 3 - 5 days

15mm Regupol 6010 SH Acoustic Screed Isolation is a recycled tyre crumb product, which has been specifically developed for heavy load bearing areas where acoustic performance is critical. This sustainable and high performing screed isolation solution delivers the greatest load bearing capacity ..

Brand: CMS Danskin Acoustics

Model and Size: 1200x1200mm - 1.44m2

Delivery Time: 1 - 2 days

10mm Acoustilay 3 is the market leading acoustic underlay product manufactured entirely in the UK, which offers all of the acoustic properties necessary to help homeowners minimise the effect of noise. The barrier mat material is manufactured using a combination of pre, mixed and post industria..

Guide Price: £57.00

£68.40 inc VAT