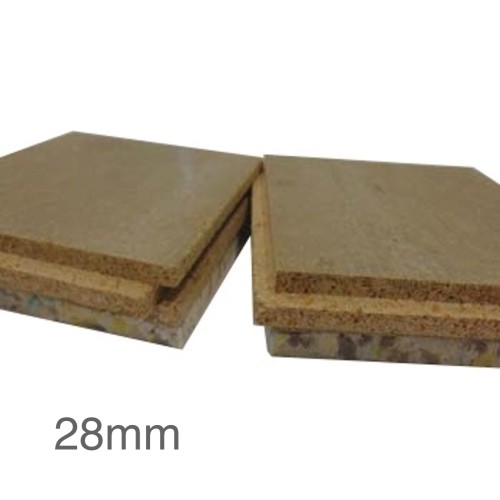

28mm JCW Acoustic Soundboard 28 Plus - Cement Particle based Acoustic Overlay Board

Guide Price

28mm JCW Acoustic Soundboard 28 Plus - Cement Particle based Acoustic Overlay Board

Guide Price: £30.94 (£37.13 inc VAT)

To add to cart change quantity to minimum of 30. If you need less, ask for a price or add to a quote list.

- Product Code: A1-1970

- Delivery Time: 2 - 3 working days

- Brand: JCW (Tech. support: 08453402858)

- Model and Size: 1200x600mm - 0.72m2

- Weight: 17.28kg

Our ratings on 23-04-2025:

4.7 out of 5 - Excellent

4.8 out of 5

28mm JCW Acoustic Soundboard 28 Plus - Cement Particle based Acoustic Overlay Board

Width: 600mm

Length: 1200mm

Board Coverage: 0.72m2

Density: 857kg/m3

Weight/m2: 24kg

Weight: 17.28kg

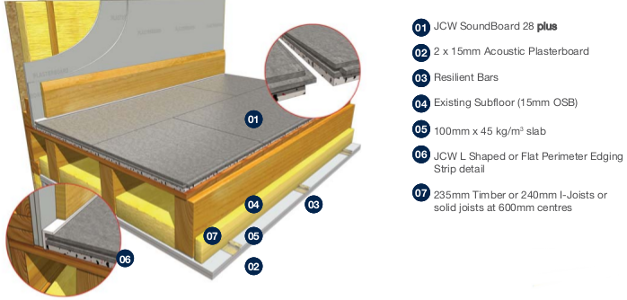

28mm JCW Acoustic Soundboard 28 Plus is an enhanced performance cement particle based acoustic overlay board for timber floors. It is designed for use as a floating overlay floor supported on decking. Soundboard 28 Plus is a durable and hardwearing acoustic decking solution. At just 28mm thick acoustic decking solution minimizes construction height but still complies with statutory building regulations. Soundboard 28 Plus is produced combining an 18mm tongue and grooved cement particle board which is laminated to a 10mm acoustic resilient layer.

- Ideal for refurbishments where floor height is an issue,

- Cement particle board ready for final floor installation,

- Economical and easy to fit,

- High performance impact and airborne sound reduction,

- Hard Wearing and Durable,

- Suitable for new builds with conventional timber joists, I-joists and metal web joists.

- Suitable for conversion projects,

- Suitable for underfloor heating

- New build

- Refurbishments

- Domestic upgrade

- On timber floors

- JCW Acoustic Soundboard 28 Plus boards are best laid towards the end of the project to protect from general trades, high floor loading and moisture leading to expansion.

- The boards are laid as a floating floor, without any mechanical fixings into the sub-floor. They are glued together as they are laid.

- Ensure that the floor surface is flat, dry, and free from all debris.

- Ensure that the wall surfaces are prepared - plaster skimmed or plaster boarded down to the level of the sub-deck and that there are no gaps at wall edges.

- Apply 5mm foam flat wall JCW Perimeter Edging Strip or L shaped strips to the base of all perimeter walls allowing approximately 15mm excess foam above the finished acoustic board height. This can later be folded down on top of the acoustic floor surface to isolate the skirting boards.

- Remove any tongues at the wall edges, then cut & scribe the first corner board into place and butt up to the Edging Strip. Do not compress the JCW Perimeter Edging Strip.

- Ensure all T&G board joints must be fully adhesive bonded using a recommended adhesive.

- Proceed with the second and successive rows ensuring that all board joints are staggered. The last row of boards will require accurate cutting & scribing to butt up to the wall.

- Any minor gaps between the JCW Perimeter Edging Strip and the acoustic board must be filled with JCW Acoustic Sealant/Mastic.

- It is imperative that the JCW Perimeter Edging Strip is not compressed in order to maintain acoustic isolation and an allowance for expansion.

- At the door threshold leave a 5mm gap between the adjoining acoustic boards and fill with JCW Acoustic Sealant. If the sub-floor at the doorways is not flat, the acoustic boards may require additional base support to reduce compressive joint movement. Additionally the surface joints could be sanded up to 5mm to level if required.

- The finished floor should not be walked on for a period of up to 24 hours to allow the adhesive to cure undisturbed.

- Ensure that the board joint adhesive has fully cured prior to overlaying any final floor covering.

JCW Acoustic Soundboard 28 Plus board has been independently tested in a UK Verified independent UKAS accredited laboratory.

Brand: JCW

Model and Size: 1000x1000mm - 1.00m2

Delivery Time: 2 - 3 working days

20mm JCW RR20 Multi-Purpose Mat is a high performance, cost effective polyurethane bound rubber granulate material, which will retain its acoustic properties throughout a long and maintenance free lifespan. It can be used successfully for a multitude of sound absorbing and impact dampening requireme..

Guide Price: £29.62

£35.54 inc VAT

Brand: JCW

Model and Size: 1200x600mm - 0.72m2

Delivery Time: 2 - 3 working days

28mm JCW Acoustic Soundboard 28 Plus is an enhanced performance cement particle based acoustic overlay board for timber floors. It is designed for use as a floating overlay floor supported on decking. Soundboard 28 Plus is a durable and hardwearing acoustic decking solution. At just 28mm thick acous..

Guide Price: £30.94

£37.13 inc VAT

Brand: JCW

Model and Size: 50mm-Free delivery

Delivery Time: 2 - 3 working days

50mm JCW Acoustic Isolating Strip is used for preventing sound transfer by isolating partitioning or party walls from ceiling and floorboards and also from joists that the floor is attached to. It can be used in all forms of construction where there is any point of contact. The strip is manufactured..

Guide Price: £23.26

£27.91 inc VAT

Brand: JCW

Model and Size: 1200x1200mm - 1.44m2

Delivery Time: 2 - 3 working days

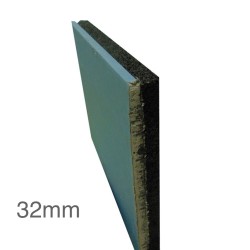

32.5mm JCW Silent Board Plus is an enhanced acoustic wall liner manufactured by laminating a 20mm acoustic resilient layer to a 12.5mm layer of acoustic grade plasterboard to drastically reduce sound transmission. It can be applied to either masonry or stud walls and is also suitable to reduce flank..

Guide Price: £74.68

£89.62 inc VAT

Brand: JCW

Model and Size: 1000x30mm

Delivery Time: 2 - 3 working days

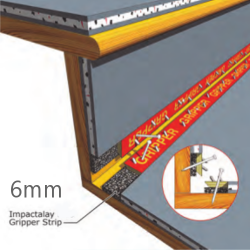

6mm JCW Impactalay Gripper Strip is an easy fitting device to prevent Impactlay plus from sliding and bunching. The JCW Impactalay plus must be installed alongside rubber JCW Perimeter Strips. It can be used on concrete, timber sub floors and stairs. Easily cut to size and simple to fit Provides a n..

Guide Price: £1.68

£2.02 inc VAT

Brand: JCW

Model and Size: 1m x 10m - 10.0m2

Delivery Time: 2 - 3 working days

10mm JCW Impacta Rubber Roll is Sound Insulation System for concrete floors, robust resilient under screed layer system. It is suitable for precast and solid concrete floors (minimum weight 300kg/m2). JCW Impacta Rubber is a tough, puncture-proof, heavy material designed for the professional buildi..

Guide Price: £162.77

£195.32 inc VAT