26mm Millboard Envello Board and Batten Cladding Board - Smoked Oak - 200mm x 3600mm

- Product Code: A1-5663

- Delivery Time: 3 - 5 days

- Brand: Millboard

- Model and Size: 200mm x 3600mm - 0.72m2

- Weight: 7.80kg

4.7 out of 5 - Excellent

26mm Millboard Envello Board and Batten Cladding Board - Smoked Oak - 200mm x 3600mm

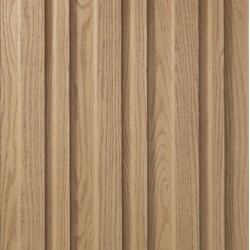

26mm Millboard Envello Board & Batten Cladding Board - Smoked Oak is a remarkable exterior solution that that replicates traditional timber batten-on-board cladding and the look and feel of real wood. Millboard Envello Board and Batten Cladding combines aesthetics and performance for a remarkable outdoor experience. The Board & Batten profile is moulded from four individual pieces of timber with varying widths and grain patterns. This creates a unique balance suitable for both contemporary and traditional designs. The tongue and groove profile ensures hidden fixings, enhancing the overall appearance. Envello Board & Batten Cladding is 100% wood-free and doesn’t require sealing to prevent moisture ingress. It’s made using a unique fibreglass reinforced resin-mineral composition, achieving a high-quality finish with maximum durability.. Millboard cladding is UK-made, reflecting British craftsmanship, innovation, and quality.

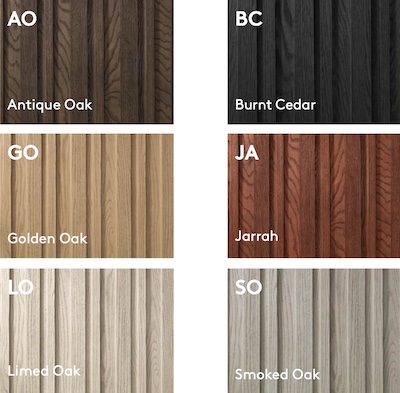

Available colours,

It is advisable to add 5-10% wastage allowance and add extra boards for window reveals depending on reveal depth.

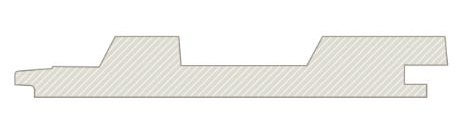

Usage: 1.53 boards per m2

Visible surface: 181mm (19mm overlap)

CHARACTERISTICS

CHARACTERISTICS- Composed of a unique blend of mineral polymer and natural fibres,

- Has a larger grain detail, enhancing its visual impact,

- Durable, resistance to moisture, and needs minimal maintenance,

- 100% wood-free, eliminating the risks associated with traditional timber, such as rotting, warping, and insect damage.

- Stands up to the harshest weather conditions,

- UV-stable, which means they won’t fade or degrade when exposed to sunlight,

- Colour fast,

- Easy to install,

- Easily cut with a handsaw, guillotine, electric jigsaw or circular saw,

- Crafted with fire retardants, making them suitable for low-rise residential and some commercial properties,

- Matching trims,

- Require minimal maintenance due to their non-porous composition,

- Regular cleaning with water and a soft brush is sufficient.

- Examine the substrate (wall) for any damage, rot, or unevenness. Repair or replace as needed.

- Install a breathable membrane (such as Tyvek) to protect against moisture.

- Fix vertical battens (usually treated timber) to the wall at regular intervals. These provide a secure fixing point for the cladding.

- Begin with a starter trim at the base of the wall. This ensures a neat finish and allows for expansion.

- Fix the first Envello board to the battens, ensuring it’s level and plumb. Use stainless steel screws or hidden fasteners.

- The tongue-and-groove profile allows boards to interlock. Slide the next board into place, securing it as before.

- For Board & Batten, add vertical battens over the joints between boards. These cover the gaps and create the classic look.

- Repeat the process, alternating between full boards and battens until the wall is covered.

- Finish with a top trim to cap the cladding.

- Seal any exposed cut edges with Millboard’s touch-up paint.

- Leave small gaps (around 5mm) between boards to allow for expansion and contraction.

- Ensure adequate ventilation behind the cladding to prevent moisture buildup.

- Envello Cladding is low-maintenance, but periodic cleaning may be necessary. Use a soft brush or mild detergent.

- Around windows and doors, follow specific details provided in the guides (horizontal and vertical).

- Has been tested to BS EN 13501-1 and holds a classification of Euroclass D