24mm JCW Acoustic Soundboard Supreme 24 - MDF based Acoustic Overlay Board

Guide Price

24mm JCW Acoustic Soundboard Supreme 24 - MDF based Acoustic Overlay Board

Guide Price: £28.82 (£34.58 inc VAT)

To add to cart change quantity to minimum of 50. If you need less, ask for a price or add to a quote list.

200 or more £30.81 (£36.97 inc VAT)

300 or more £29.28 (£35.14 inc VAT)

400 or more £27.81 (£33.37 inc VAT)

- Product Code: A1-1969

- Delivery Time: 2 - 3 working days

- Brand: JCW (Tech. support: 08453402858)

- Model and Size: 1200x600mm - 0.72m2

- Weight: 9.00kg

Our ratings on 23-05-2025:

4.8 out of 5

24mm JCW Acoustic Soundboard Supreme 24 - MDF based Acoustic Overlay Board

Width: 600mm

Length: 1200mm

Board Coverage: 0.72m2

Density: 37.5kg/m3

Weight/m2: 12.5kg

Weight: 9kg

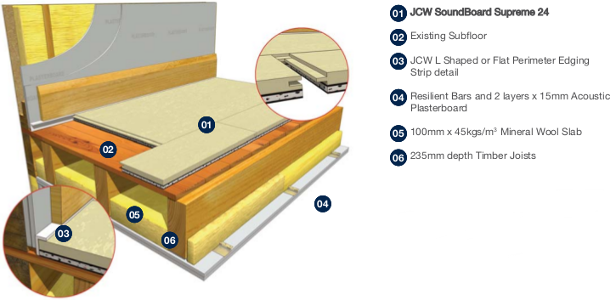

24mm JCW Acoustic Soundboard Supreme 24 is a moisture resistant 9mm T&G MDF Board with a pre-bonded 15mm high performance resilient layer offering an excellent airborne and impact sound reduction. This is one of the quickest and most effective acoustic solutions on the market. 24mm thickness the JCW Soundboard Premium 21 minimises construction height whilst still complying with statutory regulations. Overlaying the floor with an isolating layer and a new hard wearing surface is the most convenient way of dramatically improving the airborne and impact sound performance of an existing floor.

- An ideal solution where construction heights are a problem,

- Easy to install,

- Ideal acoustic overlay board for existing timber floors,

- Exceptional impact sound performance,

- Effectively improves airborne sound insulation,

- Complies with Part E of the Building Regulations,

- Ready for final floor installation

- New build

- Refurbishments

- Domestic upgrade

- On timber floors

- JCW Acoustic Soundboard Supreme 24 boards are best laid towards the end of the project to protect from general trades, high floor loading and moisture leading to expansion.

- Ensure that the floor surface is flat, dry, and free from all debris.

- Ensure that the wall surfaces are prepared - plaster skimmed or plaster boarded down to the level of the sub-deck and that there are no gaps at wall edges.

- Apply 5mm foam flat wall JCW Perimeter Edging Strip or L shaped strips to the base of all perimeter walls allowing approximately 15mm excess foam above the finished acoustic board height. This can later be folded down on top of the acoustic floor surface to isolate the skirting boards.

- Remove any tongues at the wall edges, then cut & scribe the first corner board into place and butt up to the Edging Strip. Do not compress the JCW Perimeter Edging Strip.

- Ensure all T&G board joints must be fully adhesive bonded using a recommended adhesive.

- Proceed with the second and successive rows ensuring that all board joints are staggered. The last row of boards will require accurate cutting & scribing to butt up to the wall.

- Any minor gaps between the JCW Perimeter Edging Strip and the acoustic board must be filled with JCW Acoustic Sealant/Mastic.

- It is imperative that the JCW Perimeter Edging Strip is not compressed in order to maintain acoustic isolation and an allowance for expansion.

- At the door threshold leave a 5mm gap between the adjoining acoustic boards and fill with JCW Acoustic Sealant. If the sub-floor at the doorways is not flat, the acoustic boards may require additional base support to reduce compressive joint movement. Additionally the surface joints could be sanded up to 5mm to level if required.

- The finished floor should not be walked on for a period of up to 24 hours to allow the adhesive to cure undisturbed.

- Ensure that the board joint adhesive has fully cured prior to overlaying any final floor covering.

JCW Acoustic Soundboard Supreme 24 board has been independently tested in a UK Verified independent UKAS accredited laboratory.

Brand: JCW

Model and Size: 2400x600mm - 1.44m2

Delivery Time: 2 - 3 working days

37mm JCW Acoustic Deck 37C is a 15mm resilient acoustic layer laminated to a 22mm T&G chipboard, designed for fitting direct to joist. Acoustic Deck 37 is specially designed for direct to joist fitment after existing timber floor has been removed. After removing existing timber floors, there is no n..

Guide Price: £66.50

£79.80 inc VAT

Brand: JCW

Model and Size: 1200mm x 1200mm - 1.44m2

Delivery Time: 2 - 3 working days

14.5mm JCW Noiseboard 5 is an acoustic wall liner manufactured by laminating a 2mm acoustic resilient layer to a 12.5mm layer of acoustic grade plasterboard to drastically reduce sound transmission. It is a high-performance acoustic overlay improvement board, specifically designed for both new and e..

Guide Price: £30.19

£36.23 inc VAT

Brand: JCW

Model and Size: 1200mm x 600mm - 0.72m2

Delivery Time: 2 - 3 working days

15mm JCW ImpactaLay Plus Acoustic Mat is a remarkably cost-effective and one of the quickest and most effective acoustic solutions on the market. It increases airborne sound insulation and reduces impact noise transmission so much that there is no need for the installation of false floors or false w..

Guide Price: £28.84

£34.61 inc VAT

Brand: JCW

Model and Size: 300x170mm

Delivery Time: 2 - 3 working days

300x170mm Fire and Acoustic Downlighter Cover is designed to help maintain the fire resistance and acoustic integrity of ceilings. It is ventilated to reduce heat build up.CHARACTERISTICSPractical: The downlighter covers allow light fittings to operate without overheating.Resistant: the fire rating ..

Guide Price: £65.63

£78.76 inc VAT

Brand: JCW

Model and Size: 300mm - free delivery

Delivery Time: 3 - 5 days

300mm JCW Acoustic Isolating Strip is used for preventing sound transfer by isolating partitioning or party walls from ceiling and floorboards and also from joists that the floor is attached to. It can be used in all forms of construction where there is any point of contact. The strip is manufacture..

Brand: JCW

Model and Size: 1200mm x 2000mm - 2.40m2

Delivery Time: 2 - 3 working days

4mm JCW Acoustic Barrier Mat is an acoustic barrier matting that offers very good airborne performance across the frequency range. It is a very versatile and dense product that is used for a wide range of applications where airborne sound reduction is required. The most common installation areas are..

Guide Price: £56.82

£68.18 inc VAT