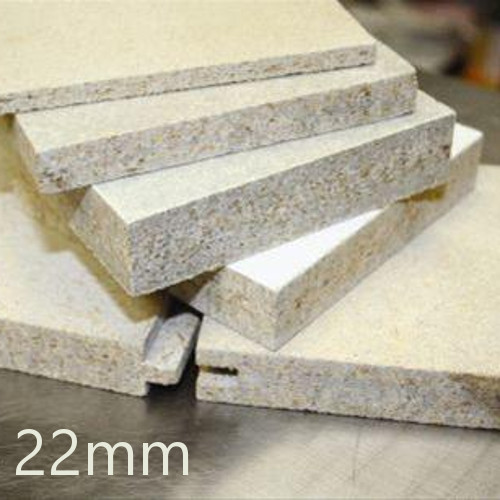

22mm Versapanel Cement Bonded Particle Board

- Product Code: A1-1741

- Delivery Time: 2 - 3 weeks

- Brand: Euroform (Tech. support: 01925860999)

- Model and Size: 2400x1200mm - 2.88m2

- Weight: 82.37kg

4.7 out of 5 - Excellent

22mm Versapanel Cement Bonded Particle Board

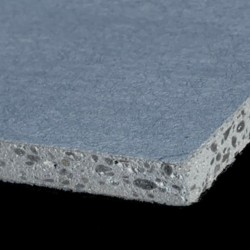

22mm Versapanel cement bonded particle board is an innovative building material that is durable and flexible and meet the requirements of moisture tolerance and fire resistance. It is manufactured from wood particles and cement and has no asbestos or other hazardous volatiles. The board has smooth grey surface and is available in two basic finishes unsanded (suitable for many decorative finishes) and calibrated (sanded on both sides). The panel is easy to use in external and internal applications due to its flexibility--can be nailed, screwed, drilled, routed, sanded, planed or sawn. It is not subject to weather influences and also provides a level of airborne sound reduction--can be used to comply with the applicable regulations. Very high compressive strength of 15N/mm2

APPLICATION- In residential and public buildings,

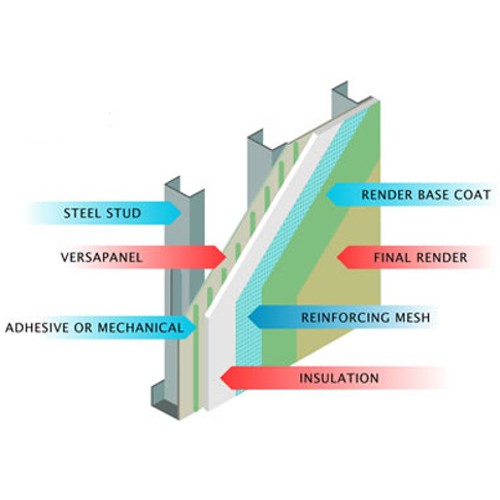

- Internal walls and partitions,

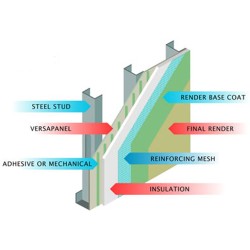

- As an external cladding material (single skin and sandwich application),

- As a structural member,

- As a carrier panel in various cladding systems, including brick slips systems, terracotta cladding systems, coating and insulated render systems.

- Acoustic Floors, Roof and Ceilings

- Non-toxic and asbestos-free,

- Durable, flexible and cost-effective,

- Offers a level of acoustic insulation,

- Easy to handle, install and decorate,

- Highly moisture and fire resistant,

- Insects, vermin and fungi resistant,

- Robust and impact resistant,

- Does not build up static charges.

INSTALLATION

- The boards need to be stored flat and if stored outside they need to be protected from the weather.

- Use tungsten carbide tipped blades--cross cut hand saw, jigsaw, portable circular saw or fixed saw.

- Milling requires common carbide-tipped tools.

- Drilling can be done with portable drilling machines, whereas no percussion drilling is required.

- Sanding can be done by using a vibrating sanding machine or belt sanding machine. It is recommended that a vacuum dust extractor is used in confined spaces.

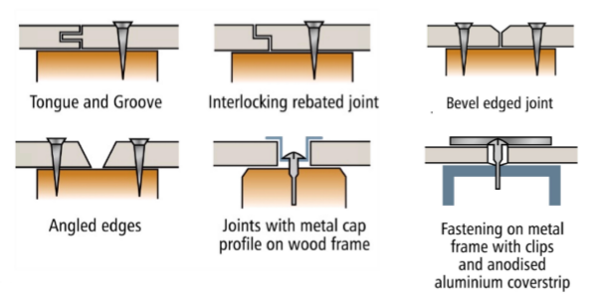

- The fixings and joints between the panels should allow imposed movement.

- The boards can be fixed with screws, nails and staples, whereas fixing distances depend on the thickness of the board.

- It is recommended that the boards are arranged in a brick bond manner.

- Alkali resistant adhesives should be used to bond the boards onto the designated surface.

- The board should be supported on all edges with support centres up to 400mm.

- Screw holes should be oversized and screw fixings added at nominal 300mm centres.

- Class 'O' in fire performances to BS 476;

- Manufactured to the BS EN 634-1 and BS EN 634-2.