12.5mm Gyproc Wallboard TEN 1200x2400mm

Guide Price

12.5mm Gyproc Wallboard TEN 1200x2400mm

Guide Price: £13.78 (£16.54 inc VAT)

Price per m2: £4.78/m2 (£5.74 inc VAT)

10 or more £13.55 (£16.26 inc VAT)

20 or more £13.29 (£15.95 inc VAT)

30 or more £13.22 (£15.86 inc VAT)

- Product Code: A1-2242

- Delivery Time: 3 - 5 days

- Brand: British Gypsum (Tech. support: 01159456123)

- Model and Size: 1200x2400mm - 2.88m2

- Weight: 28.80kg

Our ratings on 17-04-2025:

4.7 out of 5 - Excellent

4.8 out of 5

12.5mm Gyproc Wallboard TEN 1200x2400mm

Width: 1200mm

Length: 2400mm

Board Coverage: 2.88m2

Density: 800kg/m3

Weight/m2: 10kg

Weight: 28.8kg

Thermal Conductivity: 0.190W/mK

Fire Rating (Reaction to Fire): A2(Limited combustibility)

12.5mm Gyproc Wallboard TEN is specifically engineered have mass of 10kg/m2 for internal and separating constructions in all residential projects, both new-build and refurbishment. Gyproc WallBoard TEN consists of an aerated gypsum core encased in, and firmly bonded to, strong paper liners. Gyproc WallBoard TEN plasterboard is suitable for drylining internal surfaces. This plasterboard is certified to BES 6001 achieving a rating of ‘Very Good’. Plasterboard linings provide good fire protection owing to the unique behaviour of the non-combustible gypsum core when subjected to high temperatures. Linings: ivory face paper and brown reverse side paper. Tapered edge.

CHARACTERISTICS

- Non-combustible,

- Superior acoustic performance,

- High moisture resistance,

- High density,

- Easy to handle and work with,

- Board printed with screw centre markings,

- These boards have a controlled density, with a face to which suitable gypsum plasters or decoration may be applied.

APPLICATION

For internal drylining.Note: unsuitable for use in areas subject to continuously damp or humid conditions and must not be used to isolate dampness.

INSTALLATION

- May be cut using a plasterboard saw or by scoring with a sharp knife and snapping the board over a straight edge.

- Holes for switch or socket boxes should be cut out before the boards are fixed.

- Power tools should only be used by people who have been instructed and trained to use them safely.

- Fix boards with decorative side out to receive joint treatment or a skim plaster finish.

- Lightly butt boards together. Never force boards into position.

- Install fixings not closer than 13mm from cut edges and 10mm from bound edges.

- Position cut edges to internal angles whenever possible, removing paper burrs with fine sandpaper.

- Stagger horizontal and vertical board joints between layers by a minimum of 600mm.

- Locate boards to the centre line of framing where this supports board edges or ends.

- The face (ivory side) can be plastered with either Thistle Board Finish or Thistle Multi-Finish.

- There should be the minimum of delay between completion of the lining and the commencing of plastering.

CERTIFICATIONS

- Complies with EN 520 – Type D,

- EN520: 2004, A1:2009 Gypsum Plasterboards, definitions, requirements and test methods,

- BS 476: Part 6: 1989 Method of test for fire propagation for products,

- BS 476: Part 7: 1997 Surface spread of flame tests for materials,

- EN 13501-1: 2007 + A1: 2009

Brand: British Gypsum

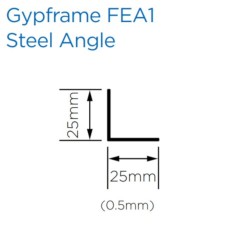

Model and Size: FEA1 - 2.9 m

Delivery Time: 1 - 2 days

British Gypsum Gypframe FEA1 Steel Angle is a folded edge angle providing improved site safety and manual handling by the use of a safer working edge, especially designed to be used with the CaoLine MF ceiling system. The angle provides..

£47.16

£56.59 inc VAT

Brand: British Gypsum

Model and Size: 1200x2500mm - 3.0m2

Delivery Time: 2 - 3 working days

12.5mm Gyproc Habito plasterboard features an engineered gypsum core with calcium sulphate dihydrate encased in paper liners. This core which provides enhanced levels of strength, durability and fixability. It provides more strength than standard plasterboard A 5mm (no. 10) wood screw in this plast..

Brand: British Gypsum

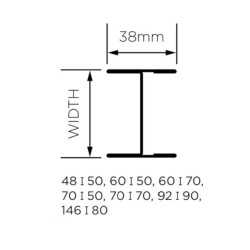

Model and Size: 92 I 90 'I' Stud - 5 m

Delivery Time: 2 - 4 days

British Gypsum Gypframe 92 I 90 5 m 'I' studs provide additional impact resistance due to the improved strength, unlike any other available Gypframe studs. They are usually used in systems with paramount board fixing strength, allowing increased partition height, but retaining the same par..

Guide Price: £355.00

£426.00 inc VAT

Brand: British Gypsum

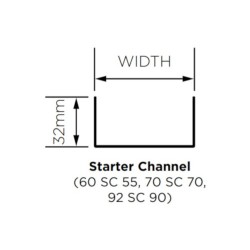

Model and Size: 70 SC 70 - 3.6 m

Delivery Time: 2 - 3 working days

British Gypsum Gypframe Shaftwall 70 SC 70 3.6 m Starter Channel is one of the available Gypframe channels, especially designed to be used with the ShaftWall System, a lightweight system which can be installed in the early construction phase, especially applicable to areas with limite..

£201.05

£241.26 inc VAT

Brand: British Gypsum

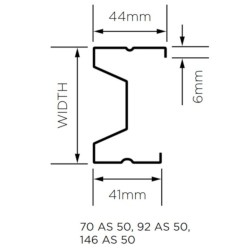

Model and Size: 70 AS 50 Acoustuds - 2.4 m

Delivery Time: 2 - 4 days

British Gypsum Gypframe 70 AS 50 2.4 m Acoustuds are made to fit 43mm, 70mm, 92mm and 146mm wall systems and considerably improve their acoustic performance due to the especially designed profile which absorbs the sound as it passes through the wall construction thus decreasing the no..

£148.95

£178.74 inc VAT

Brand: British Gypsum

Model and Size: 70 AS 50 Acoustuds - 3.6 m

Delivery Time: 2 - 4 days

British Gypsum Gypframe 70 AS 50 3.6 m Acoustuds are made to fit 43mm, 70mm, 92mm and 146mm wall systems and considerably improve their acoustic performance due to the especially designed profile which absorbs the sound as it passes through the wall construction thus decreasing the no..

£207.46

£248.95 inc VAT