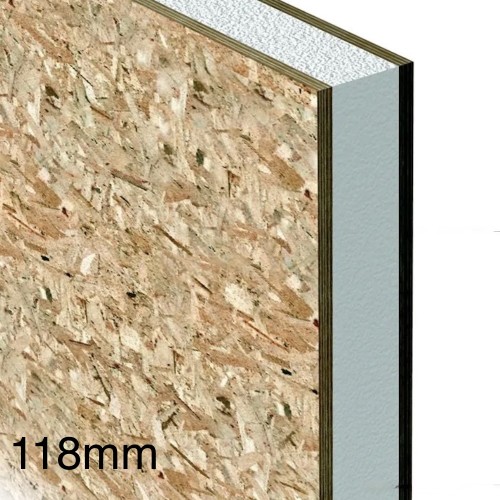

118mm Structural Insulated Panel (SIP) - Sandwich Panel (9mm OSB - 100mm EPS - 9mm OSB) - 1200mm x 2400mm

- Product Code: A1-5946

- Delivery Time: 4 - 7 days

- Brand: Various

- Model and Size: 1200mm x 2400mm - 2.88m2

118mm Structural Insulated Panel (SIP) - Sandwich Panel (9mm OSB + 100mm EPS + 9mm OSB) - 1200mm x 2400mm

118mm Structural Insulated Panel (SIP) consist of a 100mm Expanded Polystyrene (EPS) core sandwiched between two 9mm Oriented Strand Board (OSB) sheets. This advanced component offers superior strength, durability, and insulation. The OSB acts as a rigid skin, much like the flanges of an I-beam, while the EPS core prevents them from buckling, creating a monolithic, highly efficient structural unit.

This integrated design ensures high load-bearing capacity and rigidity, making SIPs ideal for walls, roofs, and floors in energy-efficient builds. Manufactured off-site, SIPs reduce on-site labour and speed up construction. Their unique structure minimises stress points and enhances resistance to wind and seismic forces, offering a significantly higher strength-to-weight ratio and overall better performance than traditional timber framing.

The OSB sheets are bonded to the EPS core under high pressure, creating a strong, rigid, and monolithic unit. This sandwich construction offers significant structural advantages. The rigid EPS core acts as a strong, lightweight load-bearing element, distributing forces evenly across the entire panel. The OSB sheets, bonded to the core, provide a continuous surface, significantly increasing the panel's shear strength and resistance to racking (lateral movement). In traditional timber frame construction, stress concentrations can occur at the joints where individual members connect. The monolithic nature of the SIP minimises these stress points, leading to a more robust and less prone to failure.

Note: Our SIP panels are level on all sides - if you want incuts in the EPS, please let us know

CHARACTERISTICS

- Comprises a 100mm thick rigid EPS insulation core.

- Sandwiched between two 9mm thick OSB sheets.

- Components bonded together under high pressure, forming a monolithic unit.

- Even distribution of forces across the panel.

- Continuous OSB surface enhances shear strength and resistance to racking.

- Minimises stress concentrations common in traditional timber frames.

- Highly rigid diaphragm resists wind loads effectively.

- Improved overall building stability.

- Enhanced resistance to lateral forces from earthquakes.

- Superior strength-to-weight ratio compared to traditional timber framing.