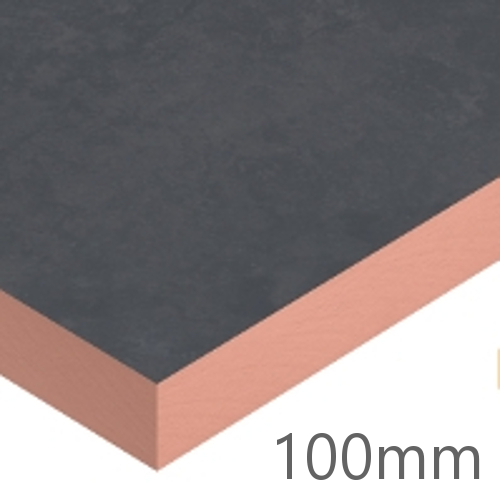

100mm Kingspan Kooltherm K106 Phenolic Cavity Board (pack of 5)

100mm Kingspan Kooltherm K106 Phenolic Cavity Board (pack of 5)

- Product Code: A1-1931

- Delivery Time: Pre-Order

- Brand: Kingspan (Tech. support: 01544388601)

- Model and Size: 1200x450mm - 2.70m2

- Weight: 10.80kg

Product discontinued.

Click Get Best Price to request a quotation and we will recommended an equivalent product.

Our ratings on 17-04-2025:

4.7 out of 5 - Excellent

4.8 out of 5

100mm Kingspan Kooltherm K106 Phenolic Cavity Board (pack of 5)

Width: 450mm

Length: 1200mm

Pack Quantity: 5

Pack Coverage: 2.7m2

Density: 40kg/m3

Weight/m2: 4kg

Weight: 10.8kg

Thermal Conductivity: 0.018W/mK

R-Value: 5.55m2K/W

Compressive Strength: 100kPa

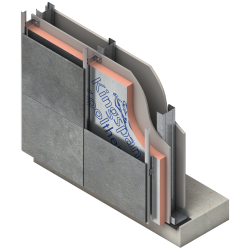

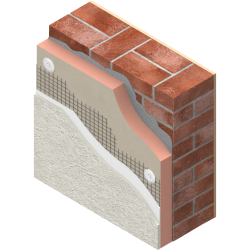

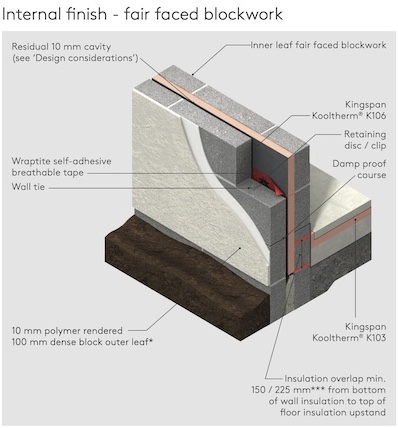

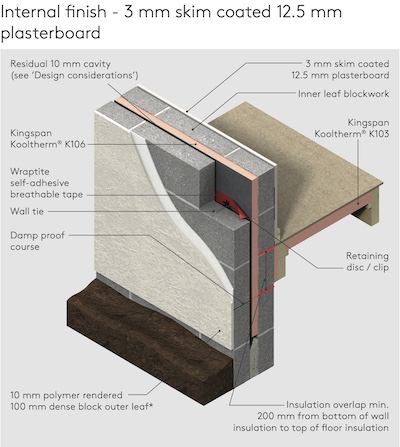

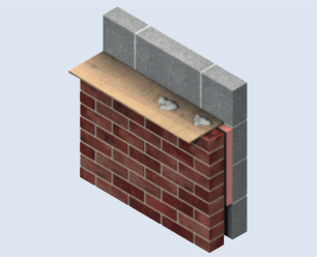

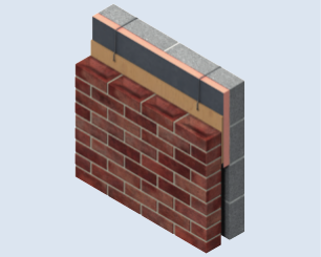

100mm Kingspan Kooltherm K106 Cavity Board is a premium performance rigid thermoset fibre-free phenolic insulation core bonded to a water-tight, vapour-open polypropylene fleece and to a inner facing (adjacent to the inner leaf) of a low emissivity composite foil. It is specifically designed to limit thermal bridging and uncontrolled air leakage via junctions in cavity wall constructions. A 10mm residual cavity width is recommended between the insulation and the outer leaf for wall heights up to 25 metres. The NHBC accepts the use of Kingspan Kooltherm K106 Cavity Board with a 10mm residual cavity, except for fair-faced masonry applications in areas of very severe exposure.

CHARACTERISTICS - Excellent thermal conductivity,

- 10mm cavity is maintained resists moisture penetration,

- The watertight, vapour-open polypropylene fleece outer facing protects against moisture penetration,

- Unaffected by air infiltration,

- Easy to handle and install.

- Kooltherm K106 Cavity Board is normally held in position by the wall ties used to tie the two skins of masonry together,

- Wall ties should include a retaining disc of a thickness <10 mm,

- For a solid concrete ground floor the first row of wall ties are installed in the inner leaf at 600mm horizontal centres, a minimum of one course of blockwork below the damp proof course, or 150mm below the top surface of the ground floor perimeter insulation upstand, whichever is the lower,

- For a suspended timber floor the first row of wall ties are installed in the inner leaf at 600mm horizontal centres a minimum of 200mm below the top surface of the ground floor perimeter insulation upstand,

- Continue constructing the inner leaf up to the next wall tie course (450mm above the first usually 2 block courses),

- The next course of wall ties is positioned at the usual 900mm horizontal centres,

- The next course of blockwork is installed to secure the ties,

- The first row of insulation boards should now be installed between the two rows of wall ties, ensuring each insulation board is retained tight against the inner leaf and joints are lightly butted,

- Each board should be secured at a minimum of three points,

- A self adhesive breathable tape, no less than 100mm wide, should be applied to all horizontal and vertical joints, board edges and abutting junction interfaces. The tape should be applied in a smooth and wrinkle free manner and should extend no less than 50mm either side of joints, board edges and abutting junction interfaces. The seal must be maintained at protrusion locations e.g. wall ties,

- The outer leaf is then built up to the level of the top of the boards and the process is repeated,

- When insulating a gable, insulation boards should be continued 200mm beyond the height of the top storey ceiling and a cavity tray installed above the insulation,

- After raising each section of inner leaf, before installation of the insulation board, excess mortar should be removed and mortar droppings cleaned from exposed edges of the installed insulation boards,

- Use of a cavity batten or cavity board to protect board edges and maintain a clear cavity,

- At the completion of each days work, or whenever work is interrupted for extended periods of time, board edges and joints should be protected from inclement weather.

- ISO 9001: 2015 (Quality Management Systems. Requirements),

- ISO 14001: 2015 (Environmental Management Systems. Requirements),

- ISO 37301: 2021 (Compliance management systems),

- ISO 45001: 2018 (Occupational health and safety management systems),

- BS EN ISO 50001: 2018 (Energy Management Systems),

BBA Certificate 16/5299.

Note: this product is non returnable.

Brand: Kingspan

Model and Size: 70mm K15 - 11.52m2

Delivery Time: 1 - 2 weeks

70mm Kingspan Kooltherm K15 Rainscreen Board is a premium performance insulation solution featuring a rigid thermoset fibre-free phenolic insulation core. This advanced core is designed to deliver exceptional thermal efficiency, making it an ideal choice for rainscreen applications. The board is fac..

Guide Price: £288.17

£345.80 inc VAT

Brand: Kingspan

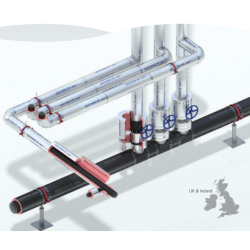

Model and Size: Kooltherm 108/15mm

Delivery Time: 1 - 2 days

Kooltherm FM Pipe Insulation comprises sections of Kooltherm FM Insulation faced with a factory-applied foil vapour barrier jacket autohesively bonded to the insulation core during manufacture. Kooltherm FM Pipe Insulation is available in a range of thicknesses to suit different performance specific..

£11.25

£13.50 inc VAT

Brand: Kingspan

Model and Size: 1200mm x 600mm - 5.76m2

Delivery Time: In Stock 1-2 working days

60mm Kingspan Kooltherm K5 External Wall Insulation Board is a premium performance external wall insulation board specifically designed for masonry walls. It features a rigid phenolic foam core, providing exceptional thermal insulation properties that help reduce energy consumption and enhance the o..

£136.67

£164.00 inc VAT

Brand: Kingspan

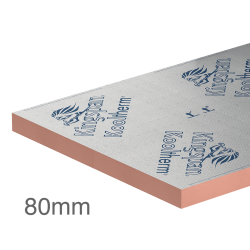

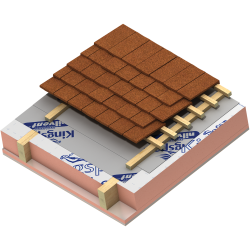

Model and Size: 2400mm x 1200mm - 11.52m2

Delivery Time: 2 - 3 weeks

80mm Kingspan Kooltherm K107 Pitched Roof Board is the rafter/joist level insulation comprising a premium performance rigid thermoset phenolic insulation core faced on both sides with a low emissivity composite foil facing. Its reflective, low emissivity surface improves the thermal resistance of an..

£372.04

£446.45 inc VAT

Brand: Kingspan

Model and Size: extensionclip

Delivery Time: 2 - 3 working days

Flange Extension Clip for connecting Kingspan Thermabate to extend the width of the fixing flange. It enables positive fixing of frame over suspect masonry. Supplied in one meter lengths. Colour coded to white.CERTIFICATIONKingspan Thermabate is manufactured to the highest standards under a manageme..

Brand: Kingspan

Model and Size: H350R 100mm - 0.75m2

Delivery Time: 3 - 5 days

Kingspan Styrozone H350R Flat Roof XPS Board is highly effective rigid insulation board made from extruded polystyrene core covered with smooth skin on both sides. It is especially designed for protected membrane flat roofs, but is also used in green roofs as a popular alternative to tradi..

Guide Price: £73.90

£88.68 inc VAT

Related Products

Brand: Proctor

Delivery Time: 999

Delivery Time: 1 - 2 days

100mm Wraptite Tape is an external air barrier that solves the problem of reliably achieving air tightness in buildings. It is self-adhered to ensure ..

Guide Price: £74.61

£89.53 inc VAT