100mm wide ARC OSCB44 - Open State Cavity Barrier for External Ventilated Cavity Walls - 75mm x 1200mm

- Product Code: A1-5545

- Delivery Time: 2 - 3 working days

- Brand: ARC Building Solutions

- Model and Size: OSCB44 - 75mm x 100mm x 1200mm

4.7 out of 5 - Excellent

100mm wide ARC OSCB44 - Open State Cavity Barrier for External Ventilated Cavity Walls - 75mm x 1200mm

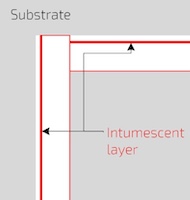

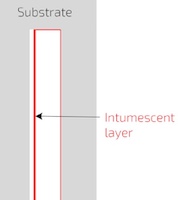

100mm wide ARC OSCB44 is a non-combustible rockfibre mineral wool cavity barrier for installation where ventilation is required in service use. It has a reactive intumescent layer, which will rapidly expand when exposed to heat in a fire event, closing off the air gap and preventing vertical fire spread within the external wall cavity. It is installed horizontally, and together with ARC Fire Stop Slab installed vertically for a complete cavity barrier solution. Air gap of 144mm is the maximum allowable. You should take in to account any contours, shapes, or profiles in the external wall system. Consider over-specifying where material or build tolerance is a concern. ARC OSCB44 is suitable for use with either concrete or masonry internal and external substrates. If used against a different non-combustible substrate it should be ensured that the wall system does not deform or deflect in such a way that could adversely affect the performance of the cavity barrier.

Note: The depth of the cavity insulation must never exceed the depth of the mineral wool element of the open state cavity barrier. Do not remove the cover.

- For 44mm air gap for ventilated cavity,

- Up to 60 minutes fire integrity,

- Quick and easy installation,

- Robust solution,

- Fixing brackets included,

- Fire rating: 60 minutes,

- Insulation performance: 60 minutes,

- Installed horizontally.

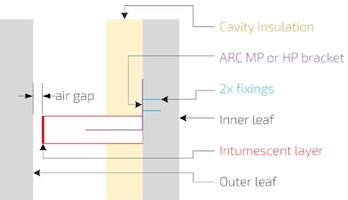

- Fold the fixing brackets in accordance with fixing specifications (see pdf table A1).

- Fix the fixing brackets to the inner leaf using appropriate non-combustible fixings for the substrate.

- The vertical leg of the brackets should be fixed so that they extend above the cavity barrier.

- Push fit the cavity barrier onto the brackets, ensuring the brackets penetrate the barrier centrally through its 75mm depth.

- Cut lengths of barrier >=200mm length must include 2 fixing brackets.

- Cut lengths <200mm must include 1 fixing bracket centrally.

- The fixing bracket should penetrate at least 75% of the depth of the barrier, except where the full size of the bracket is already smaller than this.

- The horizontal leg should also be at least 25mm short of the intumescent layer when the barrier is fully mounted on to the brackets.

- Where the horizontal open state barrier meets the vertical full fill barrier, the vertical barrier must be continuous with the horizontal ARC OSCB tightly butted to each side.

- Ensure the rear face of the barrier is tightly fitted against the inner substrate without gaps.

- Individual lengths should be butt jointed tightly together with no gaps.

- Ensure both the rock mineral wool and intumescent components are butted together tightly.

- At the extreme end of a run, or at corners, the end of the cavity barrier must tightly abut the substrate with no gaps.