100mm wide ARC OSCB25 - Open State Cavity Barrier for External Ventilated Cavity Walls - 75mm x 1200mm

100mm wide ARC OSCB25 - Open State Cavity Barrier for External Ventilated Cavity Walls - 75mm x 1200mm

- Product Code: A1-5543

- Delivery Time: 2 - 3 working days

- Brand: ARC Building Solutions

- Model and Size: OSCB25 - 75mm x 100mm x 1200mm

Our ratings on 23-04-2025:

4.7 out of 5 - Excellent

4.8 out of 5

100mm wide ARC OSCB25 - Open State Cavity Barrier for External Ventilated Cavity Walls - 75mm x 1200mm

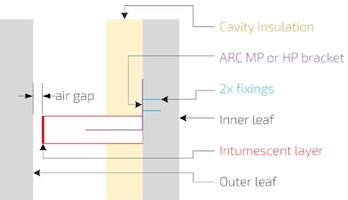

Thickness: 75mm

Width: 100mm

Length: 1200mm

Fire Protection (Resistance to Fire): 60minutes

Sleeve Colour: Red with a green strip

Note: The depth of the cavity insulation must never exceed the depth of the mineral wool element of the open state cavity barrier. Do not remove the cover.

- For 25mm air gap for ventilated cavity,

- Up to 60 minutes fire integrity,

- Quick and easy installation,

- Robust solution,

- Fixing brackets included,

- Fire rating: 60 minutes,

- Insulation performance: 60 minutes,

- Installed horizontally.

- Fold the fixing brackets in accordance with fixing specifications (see pdf table A1).

- Fix the fixing brackets to the inner leaf using appropriate non-combustible fixings for the substrate.

- The vertical leg of the brackets should be fixed so that they extend above the cavity barrier.

- Push fit the cavity barrier onto the brackets, ensuring the brackets penetrate the barrier centrally through its 75mm depth.

- Cut lengths of barrier >=200mm length must include 2 fixing brackets.

- Cut lengths <200mm must include 1 fixing bracket centrally.

- The fixing bracket should penetrate at least 75% of the depth of the barrier, except where the full size of the bracket is already smaller than this.

- The horizontal leg should also be at least 25mm short of the intumescent layer when the barrier is fully mounted on to the brackets.

- Where the horizontal open state barrier meets the vertical full fill barrier, the vertical barrier must be continuous with the horizontal ARC OSCB tightly butted to each side.

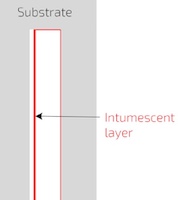

- Ensure the rear face of the barrier is tightly fitted against the inner substrate without gaps.

- Individual lengths should be butt jointed tightly together with no gaps.

- Ensure both the rock mineral wool and intumescent components are butted together tightly.

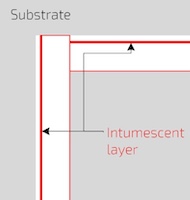

- At the extreme end of a run, or at corners, the end of the cavity barrier must tightly abut the substrate with no gaps.

Brand: ARC Building Solutions

Model and Size: CSS110

Delivery Time: 2 - 3 working days

120mm x 120mm x 1200mm ARC Cavity Stop Sock for 110mm Cavity is a non-combustible rockfibre mineral wool cavity barrier that restricts the spread of smoke and flames within the cavity of external and internal party masonry walls. It is ideally suited for providing a cavity fire barrier within the ex..

Brand: ARC Building Solutions

Model and Size: TBR150/25

Delivery Time: 2 - 3 working days

ARC T-Barrier Pitched Roof for 150mm Masonry Party Wall Cavity is a non-combustible rockfibre mineral wool cavity fire barrier that stops fire between party wall and roof covering. ARC T-Barrier Pitched Roof is designed to provide a fire, thermal and acoustic barrier between the top of the party wal..

Brand: ARC Building Solutions

Model and Size: CSS250

Delivery Time: 2 - 3 working days

260mm x 200mm x 1200mm ARC Cavity Stop Sock for 250mm Cavity is a non-combustible rockfibre mineral wool cavity barrier that restricts the spread of smoke and flames within the cavity of external and internal party masonry walls. It is ideally suited for providing a cavity fire barrier within the ex..

Brand: ARC Building Solutions

Model and Size: CSS180

Delivery Time: 2 - 3 working days

190mm x 150mm x 1200mm ARC Cavity Stop Sock for 180mm Cavity is a non-combustible rockfibre mineral wool cavity barrier that restricts the spread of smoke and flames within the cavity of external and internal party masonry walls. It is ideally suited for providing a cavity fire barrier within the ex..

Brand: ARC Building Solutions

Model and Size: for 100mm Cavity - 115mm x 500mm x 500mm

Delivery Time: 2 - 3 working days

ARC TCB Square is a faster and easier to install cavity barrier around service penetrations in external timber frame walls of low rise houses. It exceeds the Building Regulation part B fire safety norm EI30/15. ARC TCB Square provides a more robust solution, compared with either boxing in using cut ..

Brand: ARC Building Solutions

Model and Size: CSS165

Delivery Time: 2 - 3 working days

175mm x 150mm x 1200mm ARC Cavity Stop Sock for 165mm Cavity is a non-combustible rockfibre mineral wool cavity barrier that restricts the spread of smoke and flames within the cavity of external and internal party masonry walls. It is ideally suited for providing a cavity fire barrier within the ex..