What are Insulated Concrete Forms

by Mark Row

Basic Data on Insulated Concrete Forms

Basic Data on Insulated Concrete Forms

Due to the growing popularity of insulation, manufacturers in the construction business are trying to find new forms and systems that will implement insulation during the construction phase. This can not only add another layer of protection to your building but also save some money and time on separately installing a wall for example and an insulation layer. You have probably heard or even applied some modern systems available such as insulation materials with a vapour barrier pre-installed, some external wall insulation system comprising of quite a few connected elements. Well, Insulated Concrete Forms present one such solution which can help you modernize your home during construction. There have been many debates on whether these form offer more benefits than disadvantages, so we’ll try to point some of the most important ones.

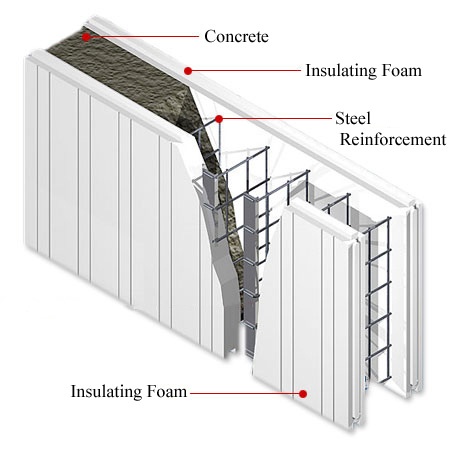

Insulated Concrete Form is basically a system consisting of reinforced concrete blocks made from foam insulation either as pre-formed interlocking blocks or as separate panels connected with plastic ties with concrete poured in between. They are made in such way to provide a solid basis for any exterior finish from stucco, bricks, wood or vinyl siding but also a basis for internal finisher such as drywall. The form is usually made of polystyrene (extruded and expanded) or polyurethane foam, cellular concrete, cement bonded wood fibre or polystyrene beads with concrete poured into the cavity thus resulting in a strong structural element. Another valuable feature is that the system can also have mechanical runs for plumbing and wiring so that you do not have to cut the cement core.

Insulated Concrete Form System

Besides the differences in materials, these ICF systems also differ in shape and design. Some basic categories include block systems which are much like children’s Lego blocks, since they include interlocking edges which fit easily. Another option are panel systems which have larger units connected by a tie, either installed on site or prior to delivery. Finally, there are plank systems which are outfitted with ties. Another classification includes flat systems which maintain the same thickness throughout the wall, screen greed consisted of vertical and horizontal concrete columns or greed systems which have the so called waffle pattern whit different thicknesses throughout the form.

Some Basic Characteristics of ICF Systems

Probably the most common reason people opt for Insulated Concrete Forms is that they can achieve required or prescribed R values without additional insulation layers added. Benefits of having an ICF system installed include:

- First and probably most important benefit of having one of these forms installed is increased energy efficiency achieved through preventing (or at least reducing) potential air leaks which can occur in both masonry or wood-frame constructions; avoiding thermal bridges which are a common occurrence in traditional wall constrictions without insulation added; as previously mentioned, these systems offer a relatively high R values of over 3 K·m²/W.

- The ICF systems have substantial thermal performance, resulting in lower heating and cooling bills, since some researches have shown that they can lead to over 40% less energy used for heating the inner space and over 30% less energy used to for cooling when compared to wood-frame constructions, all due to a relatively high thermal mass.

- The strength and stability they offer is another comparative advantage over traditional constructions, since they can be even up to 10 times stronger which only offers greater stability when under the influence of natural forces;

- The system also works as a moisture barrier, so no additional vapour barrier needs to be installed, since it works as a protection against mould growth, but also rot, rust and corrosion.

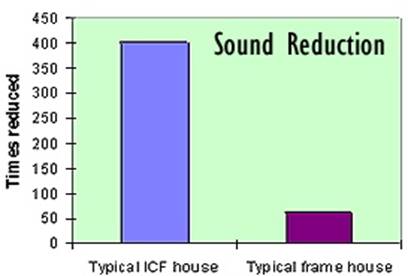

- The system also works as a sound barrier, meaning that it also has today very important acoustic insulation properties, just like traditional soundproofing materials, meaning that your home will be much quieter than with traditional wood or steel frame constructions.

- Insulated Concrete Forms also provide certain level of fire protection, with four to six hours of fire resistance, all due to the polystyrene composition which does not support combustion with less flame transmission tendency than most wooden structures.

- Finally, last but not least important thing is of course your health and the environmental impact where you can be on the safe side, since the form will not emit any dangerous contaminations upon installation and it is also partly made from recycled compounds resulting in lower carbon footprint of the whole building construction.

For more information on the ICF or any other insulation system please read the related blog articles and product descriptions on our website. If you have any questions post them in the comments below.