Easy Drylining with an Even Thinner Insulated Plasterboard

Why are Insulated Plasterboards a Perfect Solution

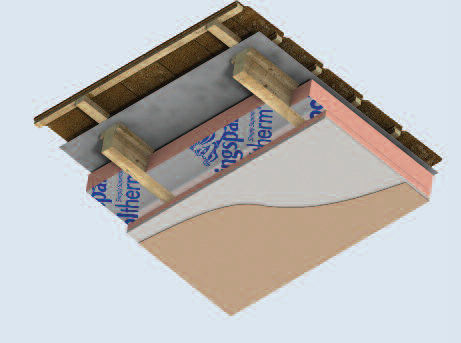

It is time to commit to easy drylining with a thinner insulated plasterboards. Namely, we believe that insulated plasterboards are a perfect solution for your DIY drylining project, due to the fact that these can be easily installed, require little or no maintenance over the years, and you get two products for the price of one – a highly efficient and resilient plasterboard and an insulation material that will keep your walls safe, sound and protected from all potentially harmful exterior effects, such as temperature fluctuations, wind loads, humidity and condensation. Depending on the preferred installation technique, whether it is the traditional dot and dab method or mechanical fixing of the boards, K13 and K14 insulated plasterboards are just the thing you need.

Kingspan K13 and K14 Properties

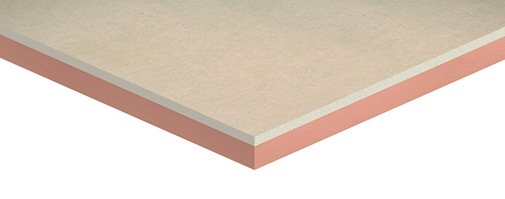

Kingspan insulated plasterboards are consisted of rigid thermoset modified resin insulant core with a gypsum plasterboard for the front facing and a glass tissue based reverse facing for K13 and low emissivity composite foil for K14, both autohesively bonded to the core during the manufacturing process. The insulation core has been manufactured with 0 ODP and low GWP, which makes both boards environmentally friendly. The boards are available in standard 2.4 x 1.2 m dimensions and various insulation thicknesses. The boards offer substantial comprehensive strength of over 100 kPa at 10% comprehension and a level of water vapour resistance of the non-plasterboard components. When designing thermal elements, make sure to take into account and calculate the condensation risk. The best way of dealing with potential condensation problems is by ensuring a continuous vapour resistance layer on the construction internal surface. Well, these insulated plasterboards come with a integral water vapour resistance layer which can provide the necessary water vapour control layer, if installed correctly. However, note that the boards are made from a gypsum plasterboard facing, why it cannot be used as a damp proof layer nor should be used in extremely humid conditions.

Their insulation core is also resistant to petrol and most mineral oils, alkalis and dilute acids, and also microbial growth and mould attack since they do not provide any food for vermin. However, the core is not resistant to some adhesives which contain methyl ethyl ketones why such adhesives should not come in contact with the boards since they might damage the boards which should then not be used. In case of any spills during preparation, make sure to fully clean the boards using only approved cleaning methods, recommended by the manufacturer.

What makes the insulation plasterboards cost-efficient, apart form their insulation power is their durability, since the boards can have indefinite life span, if installed correctly. Please note that the durability may also be affected by the durability and effectiveness of the entire construction and its elements. Another valuable fact is that the boards are Class 0 when it comes to their fire resistance characteristics, when tested in accordance with the Building regulations, which also makes them applicable to commercial and industrial sector. Probably the most important values of the boards are the ones showing their insulation value, why it is good to know that both boards offer thermal conductivity of only 0.19 W/m.K of the plasterboard and thermal conductivity of the insulation core ranging from 0.19 to 0.22 W/m.K, depending on the insulation thicknesses. Finally, the R values (given when the product thickness is divided with the thermal conductivity value) show the level of thermal resistance of the product range from 0.95 to 4.75 m2.K/W, depending on the thickness of the product (insulation core + the plasterboard).

The preparation for installing plasterboards with insulation includes proper cutting of the boards which can be done by a fine toothed saw or a sharp knife which can easily cut through the plasterboard paper backing and the insulation core, then snapping the sheet over a straight edge and cutting the plasterboard paper facing on the other side. Also, make sure that the boards are stored properly, ideally inside, but if outside storage is necessary, make sure that the boards are properly covered and protected from the weather.

Additional piece of advice when installing the thin thermal laminates refers to the potential problem with linear thermal bridging which is most likely to occur around openings in the structure, such as door and window opening, at reveals. The problem can be put under control if the reveals are also properly insulated. When doing so, make sure that the insulation used can achieve the recommended R value, which should be (in accordance with the Accredited Construction Details and Acceptable Construction Details) 0.34 m2.K/W.

For more info about the new thinner insulated plasterboards contact Insulation Shop through live chat, phone or send an email to info@insulationshop.co.