Basic Principles of Cavity Wall Insulation

by Mark Row

Cavity Walls – Is It a Problem That Needs To Be Solved?

Cavity wall insulation can drastically improve the overall thermal performance of your home. Cavity walls are very common in coastal areas where they were originally designed to protect the house from natural influences like driving rain or high wind, with usually some insulation material added later on. However, these can lead to significant heat loss in time and that is why they need to be properly insulated, using some approved methods and materials, depending on various factors like the age and the location of the building, its exposure or the construction material of the cavity wall itself. Insulation London herewith offers you some basic principles of cavity wall insulation.

Cavity wall insulation can drastically improve the overall thermal performance of your home. Cavity walls are very common in coastal areas where they were originally designed to protect the house from natural influences like driving rain or high wind, with usually some insulation material added later on. However, these can lead to significant heat loss in time and that is why they need to be properly insulated, using some approved methods and materials, depending on various factors like the age and the location of the building, its exposure or the construction material of the cavity wall itself. Insulation London herewith offers you some basic principles of cavity wall insulation.

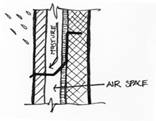

Cavity walls or also known as hollow walls are consisted of two tied masonry leaves, separated by an empty, hollow airspace in between. The outer leaf of cavity walls is used to protect the wall from external influences, like the rain, while the inner leaf carries out the internal finishes. The structural stability of the building implies that these two parts need to be properly joined in order of bearing the upper floors load, but are also separated by a cavity whose basic function is to keep the water and moisture away from the inner leaf, keeping it dry and protected from decay and damp and allowing any deposited water to evaporate. In some older cavity walls, the tie between the leaves was made out of bricks or sometimes the outer leaf was made of stone and the inner one of bricks. Later on, wrought and cast iron alongside steel ties appeared, but the problem was their exposure to corrosion.

Cavity wall cross section

There are certain precautions and measures to consider and undertake, before adding cavity wall insulation. These will help you determine whether cavity wall insulation is even possible and if so what is the best method and insulation material. First of all, you must determine the construction material of your cavity wall, which will depend on the age of the building, since same construction techniques were not used at all times. In older buildings, always pay attention to the “breathing” structure of the building, which prevents trapping of moisture. Make sure that impermeable materials used, like renders and paint, will not damage “breathing” of the building, which can affect dampness and decay problems. Another thing to consider is the thermal mass of the outer wall, which is very useful both during the summer and winter, since it can absorb some heat during the day and release it during the night, just as it can cool off the room interior during the summer. This is why it is important to maintain the external wall thermal mass when adding cavity wall insulation, where certain insulation methods are more adequate than others. Also consider climate impacts that is the building exposures to some external influences, set by its location and extensions as well as the location of surrounding structures. Finally, the presence of damp and salts and the drying-out period, depending on how long was the structure exposed to damp and moisture are another important factors to consider in cavity wall insulation.

Now, let’s move on to cavity wall insulation materials and methods. The most commonly used insulating materials in cavity wall insulation are mineral or rock wool insulants, some expanded polystyrene products and some insulating foams like urea formaldehyde foam or polyurethane foam. The insulation method will determine the material, since there are two basic ways of insulating a cavity wall, full fill and partial fill cavity insulation. While full fill cavity insulation includes insulating the whole cavity with no need for residual cavity, partial fill cavity insulation is used when there is a need of leaving a residual cavity of minimum 500 mm, in order of preventing the penetration of water.

Now, let’s move on to cavity wall insulation materials and methods. The most commonly used insulating materials in cavity wall insulation are mineral or rock wool insulants, some expanded polystyrene products and some insulating foams like urea formaldehyde foam or polyurethane foam. The insulation method will determine the material, since there are two basic ways of insulating a cavity wall, full fill and partial fill cavity insulation. While full fill cavity insulation includes insulating the whole cavity with no need for residual cavity, partial fill cavity insulation is used when there is a need of leaving a residual cavity of minimum 500 mm, in order of preventing the penetration of water.

Rock wool insulation is the most commonly used type of cavity wall insulation, consisted of mineral fiber derived from igneous rock. It is usually blown into the cavity, covering completely the airspace between outer and inner leaf, so it is most commonly used in full fill cavity insulation. Rock wool is water resistant so it stops any water from penetrating in and affecting the inner leaf of the cavity wall. Expanded polystyrene insulators are more effective in narrower cavities and can be used for both full and partial fill cavity insulation. There is also another option in partial fill cavity insulation – thin, foil-faced insulation boards using the heat radiance reduction, while meeting the required U values. When it comes to prescribed U values, it is good to know that according to the applicable regulation, that is Part L of the Building Regulations, targeted U values are 0.55 W/m2K when there is a possibility of adding insulation and 0.30 W/m2K when there is no such possibility.

Now that you know some basic principles of cavity wall insulation, know that InsulationLondon.co can offer you high quality products for both full and partial fill cavity insulation, produced by leading names in the insulating industry today like Knauf, Rockwool, URSA, Kingspan, Celotex and Xtratherm. You can opt for Knauf Standard or Ultimate Cavity Slab (link), applicable in both full and partial fill cavity insulation, Rockwool Cavity Insulation, available in lightweight non-combustible batts, ready to use in every purpose group building or URSA Cavity Insulation Batts, being resilient and very easy to install, also enhancing acoustic insulation of the building.

Now that you know some basic principles of cavity wall insulation, know that InsulationLondon.co can offer you high quality products for both full and partial fill cavity insulation, produced by leading names in the insulating industry today like Knauf, Rockwool, URSA, Kingspan, Celotex and Xtratherm. You can opt for Knauf Standard or Ultimate Cavity Slab (link), applicable in both full and partial fill cavity insulation, Rockwool Cavity Insulation, available in lightweight non-combustible batts, ready to use in every purpose group building or URSA Cavity Insulation Batts, being resilient and very easy to install, also enhancing acoustic insulation of the building.

Finally, there are Kingspan Kooltherm Cavity Boards, especially designed for partial fill cavity insulation, properly certified and unaffected by air infiltration or Celotex Rigid PIR Cavity Insulation Board, also designed for partial fill cavity insulation, including low emissivity foil facings and having substantial dimensional stability.

Feel free to share your opinion on Cavity Wall Insulation in the comments section below. I will be happy to answer all your questions.