Renderflex and Rendaboard Comparative Review

Perfect Solutions for Direct Render Applications

If you are planning on or you have already started building your home (or undertaking some refurbishment work), you need all necessary information on each construction detail, all in order of being satisfied with the final result, which is not always an easy task. Namely, if you are not familiar with the construction industry (which is usually the case) then you may have hard time choosing the best solution which can depend on many things including the results you are expecting, the location of your home, your budget etc. Basically, all these things need to be reconciled and balanced in order of optimizing the result. For example, if you have decided to apply some direct render system, you will need a proper base board that will be resistant enough, durable and compatible with the chosen polymeric coating system. Well, if this is the case with you, then you have come to the right place, since we herewith offer a solution in Renderflex and Rendaboard comparative review.

Renderflex and Rendaboard Characteristics

Ok, let’s start from the top and consider some Renderflex and Rendaboard basic characteristics. As before mentioned these are; render carrier boards, specially designed for direct render applications. Both boards have composure which allows their high compatibility and flexibility, necessary for different coating systems – Renderflex is a cellulose/fibre cement board, containing mostly cellulose fibres, san and Portland cement while Rendaboard is made from glass and wood fibre, non-woven clothes and water mixture, offering a textured face to one side, but also non-toxic, which can be very important, depending on the application.

Both boards are available in standard 2400 x 1200 size, just as they can both be found in 9mm and 12mm thicknesses, but Renderflex also offers a thinner solution in 6mm boards. If you are looking for a base board for industrial application, it is good to know that both boards are Class 0 rated in reference to their fireproofing performance, just as they both offer substantial strength, durability and dimensional stability. What also contributes to Rendaboard and Renderflex durability and great performance is their high biological and moisture resistance, making them applicable in various settings and humid environments. Finally, what is especially important to mention is the fact that both boards offer a level of soundproofing which can be very useful in both commercial and residential applications, especially bearing in mind the minimal level of acoustic insulation prescribed by applicable Building regulation. When speaking of compliance, please note that both products have been properly tested and have all necessary certifications proving their harmonization with prescribed standards in the construction industry.

Renderflex and Rendaboard Application and Installation

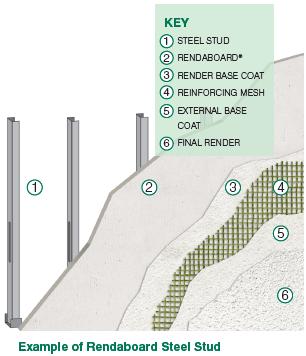

As upper mentioned, both Renderflex and Rendaboard are suitable for direct render applications and compatible with different types of coating, due to their flexible structure and texture. Both boards can be used in new build and refurbishment projects, whereas Renderflex is most commonly used in internal and external wall linings while Rendaboard is suitable for both steel and timber frame constructions. However, please note that Renderflex is primarily designed as an external base board, where no insulation is added to the structure. In case you are planning on adding another layer of insulation to your wall, them the manufacturer advises to use some alternatives that are more suitable and compatible with the chosen type of insulation material.

Another vital advantage of both Rendaboard and Renderflex is their easy installation and low maintenance, which will lower your costs. Basically, once the boards have been delivered, you can simply install them yourself (of course following the given instructions and especially making sure that all safety and health precautions have been acted upon) and be sure that they will last for a long time with no special maintenance and care necessary upon installation, especially bearing in mind the 30 year durability provided by Renderflex boards.

When transporting and storing these render carrier boards, it is important to make sure that they are not anyhow damaged by weather conditions (why they should be stored in dry conditions or properly covered and protected with some weatherproof sheating). Their flexible and fibre structure allows easy cutting and drilling where you will not need any specialized tools, but can use tooth or power saws. When installing Rendaboard, it is important to leave a 50mm ventilated air cavity and to stack the boards in brick bond pattern, using stainless steel self-countersinking and self-drilling screw fixings. As for Renderflex board, fixing pattern should be based in 600mm centres and the distance between the fixings and the board edge at least 12mm and 50mm in from corners of the board.

Insulation Shop offers Renderflex and Rendaboard at affordable prices and big discounts. Send your quote enquiries to info@insulationshop.co or order directly from our insulation webshop.