Adhesives and Base Coats for Insulated Render Systems

Adhesives and Base Coats for Insulated Render Systems: The Key to Successful Exterior Wall Insulation

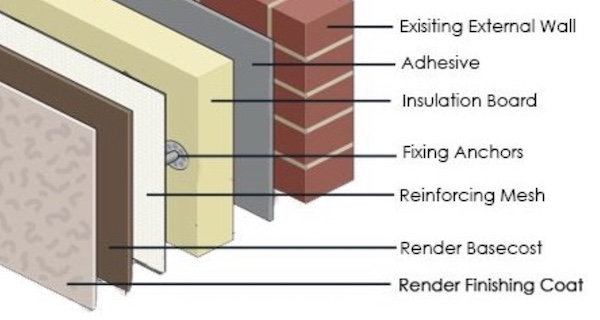

Exterior Wall Insulation (EWI) is a popular and effective way to improve the energy efficiency of a building, reduce heating and cooling costs, and enhance the overall aesthetic of a property. At the heart of an effective Insulated Render System are the adhesives and base coats, which play a crucial role in ensuring the longevity and performance of the installation.

Insulated Render systems rely on a strong, durable adhesive to bond the insulation panels to the substrate, forming the foundation of the entire installation. The choice of adhesive is crucial, as it directly impacts the long-term performance and stability of the EWI system.

The base coat is a critical component of an Exterior Wall Insulation (EWI) system, serving as the protective layer that shields the insulation from the elements and enhances the overall durability of the installation. This versatile layer not only safeguards the system but also provides a smooth, uniform surface for the final decorative finish.

Advantages of Adhesives and Base Coats for Insulated Render Systems:

- Secure Bonding: EWI adhesives provide a strong, durable bond between the insulation panels and the substrate, ensuring a stable and long-lasting installation.

- Thermal Efficiency: The base coats help to create a seamless, continuous insulation layer, minimising thermal bridges and maximising the overall thermal performance of the EWI system.

- Weatherproofing: The base coats act as a protective layer, shielding the insulation from the elements and preventing water ingress, which can compromise the integrity of the system.

- Crack Resistance: The flexible nature of the base coats helps to absorb minor movements and stresses, reducing the risk of cracks and other structural issues.

The base coats can be finished with a wide range of textures and colours, allowing homeowners to customise the appearance of their property and achieve their desired aesthetic.

Types of EWI Adhesives:

- Cement-based Adhesives:

- Composed of cement, sand, and various additives

- Provide a strong, rigid bond between the insulation and substrate

- Suitable for a wide range of substrates, including masonry, concrete, and rendered surfaces

- Polymer-modified Adhesives:

- Contain cement as the base, with the addition of polymers

- Offer improved flexibility and crack resistance compared to traditional cement-based adhesives

- Particularly useful for substrates that may experience movement or vibration

- Dispersion Adhesives:

- Water-based, polymer-emulsion adhesives

- Provide a flexible, durable bond

- Suitable for use on smooth, non-porous substrates, such as metal or existing renders

Types of EWI Base Coats:

- Cement-based Base Coats:

- Composed of cement, sand, and various additives

- Offer good resistance to weathering and impact

- Provide a rigid, durable base for the final finish

- Acrylic-based Base Coats:

- Water-based, polymer-modified formulations

- Offer improved flexibility and crack resistance

- Suitable for use on a wide range of substrates

- Hybrid Base Coats:

- Combine the benefits of cement and acrylic-based formulations

- Provide a balance of strength, flexibility, and weather resistance

Installing EWI Adhesives and Base Coats:

- Surface Preparation: Ensure the substrate is clean, dry, and free from any loose or flaking material.

- Adhesive Application: Apply the EWI adhesive to the back of the insulation panels using the appropriate method (e.g., notched trowel, spot-bonding).

- Panel Placement: Firmly press the insulation panels into the adhesive, ensuring they are level and aligned.

- Base Coat Application: Once the adhesive has cured, apply the base coat to the surface of the insulation panels, using a suitable tool (e.g., trowel, roller).

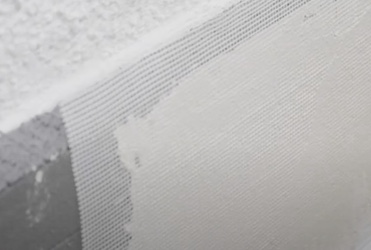

- Reinforcement: Embed a reinforcing mesh into the base coat, overlapping the joints and edges to create a seamless, reinforced layer.

- Finishing Touches: Allow the base coat to dry completely, then apply any additional coatings or finishes as required (e.g., render, paint).

Differences between EWI Adhesives and Base Coats:

- Purpose:

- Adhesives are used to bond the insulation panels to the substrate.

- Base coats are applied over the insulation panels to create a protective and reinforced layer.

- Adhesives are used to bond the insulation panels to the substrate.

- Composition:

- Adhesives are typically cement-based or polymer-modified, designed to provide a strong, durable bond.

- Base coats are usually acrylic or cement-based, formulated to be flexible and crack-resistant.

- Adhesives are typically cement-based or polymer-modified, designed to provide a strong, durable bond.

- Application:

- Adhesives are applied directly to the back of the insulation panels or the substrate.

- Base coats are applied over the entire surface of the insulation panels.

- Adhesives are applied directly to the back of the insulation panels or the substrate.

- Thickness:

- Adhesives are typically applied in a thin, even layer.

- Base coats are applied in a thicker, more uniform layer, usually between 3-6 mm.

- Adhesives are typically applied in a thin, even layer.

Similarities between EWI Adhesives and Base Coats:

- Compatibility:

- Both are designed to be compatible with the insulation materials and other components of the EWI system.

- Durability:

- Both are formulated to be weather-resistant, flexible, and able to withstand the stresses and movements of the building.

- Reinforcement:

- Both can be reinforced with mesh or other materials to enhance their strength and crack resistance.

- Finishing:

- Both can be finished with a wide range of textures and colours to achieve the desired aesthetic.

- Importance:

- Both play a critical role in the overall performance and longevity of the EWI system, ensuring a secure, weatherproof, and energy-efficient installation.

By choosing high-quality adhesives and base coats for your Insulated Render System, and following the proper installation procedures, homeowners and contractors can ensure a durable, energy-efficient, and visually appealing exterior wall insulation system that will stand the test of time.