Renders and Adhesives

Rendering is an easy way to update a home and hide surface imperfections. Render can be applied on both new and existing homes and is great for creating a modern look that is low maintenance. Render is usually applied to brick, concrete, cement or stone surfaces but it can also be applied to mud brick walls and so on. It is suitable for exterior walls, interior walls, mailboxes, and fences, indeed anything that is made from the above materials. Render can be neutral, coloured or painted.

Acrylic renderAcrylic render is a finishing coat for render, containing acrylic aggregates to display an attractive finish. Because of this, it is much more resistant to cracking than other types of render. It is also fast drying, taking only two days to cure and dry while traditional renders can take up to 28 days. Acrylic render can be used to cover up small hairline cracks in masonry surfaces. Acrylic renders incorporate anti-cracking technology by using minute reinforcing fibres to produce an incredibly tough and durable finish. It is permeable to water vapours, it allows the materials underneath (brick etc) to breathe. It is also resistant to efflorescence, which is the white salts that sometimes leaks from brickwork. Acrylic render can be trowelled on or rolled or even sprayed onto a surface. Two coats are generally applied.

Acrylic render is available in a wide range of colours and textures ranging from 1mm to 3mm aggregate size. It is applied to new and existing render to seal the substrate layer and enhance the appearance of the elevation. Suitable substrates: Light weight thin coat render systems, cement render and brick and stone.

Mineral render

Mineral Render is eco-friendly, manufactured from natural materials such as mineral aggregates, and white marble grain. It is available with a rolled texture in 2, 3 and 4mm grain sizes. Mineral Render is highly damage resistant and also is Class 0 surface spread of flame. Mineral render contains cement contact allowing the product to set quicker, so it can be easily used in during lower temperature periods.

Buy Mineral RenderMosaic render

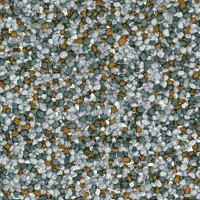

Flexible and easy to clean render with increased scratch resistance and covering ability. Suitable for indoor and outdoor use on walls exposed to high wear: at plinths, entrances, hallways, window and door reveals. Sealing component: transparent resins. Filler: coloured quartz stone. Can be applied and smoothed with stainless steel trowels. Produces a glassy, colourful coat upon setting. Mosaic render can be used on concrete substrates and traditional plasters etc.

Silicone render (Polymer render)

Polymer render is a cement based system with specially selected polymers added to the mix. These polymers make the finished coat strong yet flexible, allowing them to be used on a number of substrates. Polymer renders incorporate silicone water repellents as an integral part of the cement based render system. This silicone technology allow water vapour to pass through the render, letting the substrate breathe. The use of nylon reinforced base coats provides a high strength base for the finish coat. Polymer render is available as one coat render, eliminating the need for a base coat. Polymer renders come in a wide range of colours and can be finished in different textures, from a flat sponged float finish or a rougher scraped finish as well as Pebble Dash.

They are usually premixed and only require the addition of clean water to produce the final product. This ensures the quality of the render remains consistent and ensures a superior finish.

Applying Render

- Rendering should be done in good weather. It should not be done in direct sunlight or in areas that are subjected to winds.

- The surface to be rendered needs to be wetted so that the wall is damp but not glistening with moisture.

- Cement render in particular should be kept damp between coats or for three days. This is so the render does not crack while it is setting.

- The main problem with rendering is getting the render to adhere to the surface. To make this easier, the surface can be roughened (especially if it is smooth – like concrete) or a special preparation may be applied to the wall and added to the render.

- The render should suit the surface which it is being applied to and be applied in the correct thickness.

- Most renders take two or three coats but this is dependent on the surface being rendered, and which render you are opting to use.

Fixing external wall insulation boards

- The ready adhesive mortar should be applied with a trowel along the board edges forming a strip of 3÷4 cm wide and a few spots with the diameter of approx. 8 cm.

- The board should be pressed to the wall with a few slight blows of a long float.

- The properly applied adhesive mortar when pressed should cover minimum 40% of its surface.

- The ready mortar of 3÷4 cm-thick layer should be spread along the surface of the boards by means of a smooth long steel float.

- The glass fibre mesh should be applied on the fresh mortar with 10-cm overlaps, and then the second 1-2cm-thick layer should be applied and smoothed evenly so that the glass fibre mesh should not be visible.

- Fresh stains should be cleaned with water, while hardened elements should be mechanically removed.