Cement Boards

A cement board is a combination of cement and reinforcing fibres formed into sheets. Cement boards can be used in numerous building applications. They’re primarily designed to overboard floor and walls instead of plywood to eliminate problems caused through warping and movements. It is completely unaffected by water and moisture - it simply absorbs moisture and becomes even more stronger. They are typically used as a tile backing board due to this quality. Polymer modified cement board can be fabricated in thin sheets to allow bending for curved surfaces.

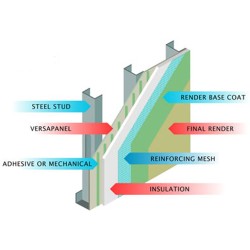

Cement board can be nailed or screwed to wood or steel studs to create a substrate for vertical tile and attached horizontally to plywood for tile floors, kitchen counters and backsplashes. It can be used on the exterior of buildings as a base for exterior render systems and sometimes as the exterior finish itself. Cement board is highly impact resistant and much stronger than gypsum boards and will not get water clogged.

Cement bonded particle board

Cement bonded particle boards have treated wood flakes as reinforcement, and are made of a homogeneous mixture and can be formed as single layer for any thickness.

Fibre cement board

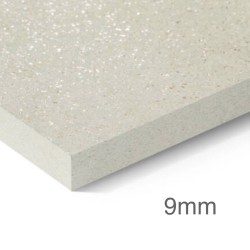

The fibre cement board has cellulose fibre as reinforcement, which is a natural element, but there can be man made fibres used as reinforcement. Fibre cement boards can be made to any thickness.

CHARACTERISTICS

- Long-term performance than paper-faced gypsum core products

- Will not mildew or physically break down in the continued presence of moisture or leaks.

- A stronger bond and support with tiles than typical gypsum board.

- Has excellent drying properties.

- A waterproofing layer can be applied over its surface.