Pitched Roof Insulation

Pitched roofs are very popular in many types of commercial and public buildings and can be constructed in two ways – with a ceiling and without a ceiling, depending on the building specification and design. Some designs do not include ceiling and the height of the pitched roof is used to create light, attractive, interiors. Some specifications require the roof void to be utilised as an additional room. When converting your attic into a room, insulation is placed in between the rafters to create a worm roof.

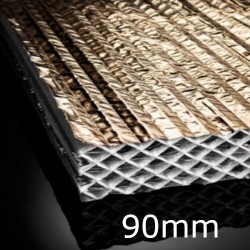

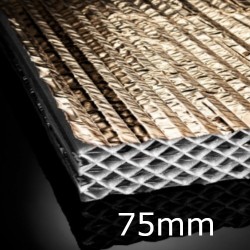

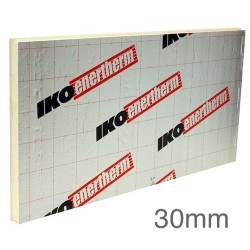

Various products can be used for pitched roof insulation: semi-rigid insulation boards such as expanded polystyrene board, extruded polystyrene board, glass fibre batts, mineral fibre batts, urethane foam board or phenolic (fireproof) foam boards. If a first layer of insulation is placed between rafters, a second, thin layer is applied to the underside of the rafters to avoid thermal bridging. Glass fibre quilt and mineral fibre quilt can also be used. A vapour check should be installed on the warm side of the insulation and ventilation above. These materials can be held in place by a plaster lining board which also provides the necessary fire protection.

Methods used for insulation will solely depend on the design and building specification.

Following choices are available:

Pitched roof with unutilised roof void insulated at ceiling level

Insulation placed at ceiling level creates a cold roof space; and overall is the lowest cost option for insulating a roof due to a low quantity of insulation material needed. High levels of thermal insulation can be achieved because there is virtually no restriction on the thickness of insulation that can be installed. There are two options when insulating at ceiling level to provide sufficient ventilation of the roof and eliminate moisture condensation; insulating to achieve:

- Cold ventilated roof:

- Cold ‘breathing' roof:

Cold ventilated roof insulated at ceiling level contains no vapour control layer; instead, water vapour enters loft through gaps and cracks in ceiling and by diffusion through ceiling plaster. Impermeable bituminous felt underlay placed underneath tiles and slates traps moisture in loft. To eliminate condensation, ventilation trays are created at the eaves of pitched roof to provide clear air path above insulation. Air continuously enters loft through the ventilation trays and leaves through the ridge gap on top of the roof providing cross ventilation to eliminate vapour and defuse moisture, leaving the loft space cold, draughty and dusty.

In a more modern cold ‘breathing’ roof insulated at ceiling level, vapour control layer is placed underneath insulation to reduce vapour entering the loft. Ventilation space is created by counter battens which allow air to circulate underneath tiles and slates providing continuous diffusion of moisture leaving the loft space clean, dry and drought free. It is recommended to use breathing roof construction for all pitched roofs.

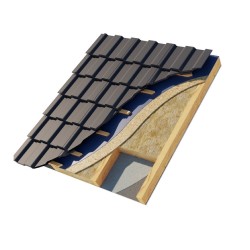

Utilised pitched roof void insulated between rafters

Several methods are used to insulate utilised roof void depending on specification. Following choices can be used:

- warm ‘breathing’ roof insulated between rafters,

- warm ‘breathing’ roof insulated above and between rafters,

- warm’ breathing' roof with vapour permeable underlay as tiling underlay

- warm ventilated roof

In a warm ‘breathing’ roof vapour control layer must be used to underside of insulation to prevent moisture condensation. In a warm ventilated roof it is essential to provide 50mm ventilated airspace between the insulation and the tiling underlay to provide constant diffusion of vapour. If rafter depth is insufficient to accommodate the required thickness of insulation and the 50mm ventilated airspace, an insulated dry lining is recommended to minimise thermal bridging. Ventilation openings should also be provided. At the eaves, ventilation openings should be 25mm continuous gap and at the ridge - 5mm continuous gap on each side of the ridge. A vapour control layer also must be applied to the warm side of the insulation.

Pitched roof with no ceiling insulated between rafters

Insulating this type of roof is a complex task and can be designed in several ways depending on specification:

- Hybrid pitched roof with a single layer insulation between rafters

- Hybrid pitched roof twin insulated; between and below rafters

Insulationshop.co offers a wide range of pitched roof insulation from manufacturers Xtratherm, Celotex, Knauf, Kay Metzeler, Cellecta and more. For more information about particular products please see product description.