Bison Composite Batten Cladding

These robust cladding planks are manufactured from 82% recycled material -- wood fibre and HDPE plastic, bonded with UV stabilisers and colour pigments. They are available in Ash Grey or Oak colours. They can be installed vertically or horizontally.

Bison composite batten cladding won’t deteriorate and need regular maintenance. These composite planks are fade resistant due to its strong UV resistance and won’t rot or splinter, scratch resistant and non- porous. They don't need any painting or staining, meaning very little maintenance throughout its life expectancy. A simple hose or jet wash would clean the surface and the grooves.

Bison composite batten cladding system with its minimal trims and planks sized ideally for vertical cladding, is a simple and easy to use system with minimal need for cutting, offering the elegant design and easy installation.

INSTALLATION

- Bison Composite Batten Cladding should be stored on a flat surface either fully supported or on timber bearers at maximum 400mm spacing.

- Standard woodworking tools may be used.

- Cladding cannot be used as primary load-bearing element.

- Cladding must be installed onto a substructure, so there is adequate and unobstructed air flow under the cladding to prevent excessive water absorption.

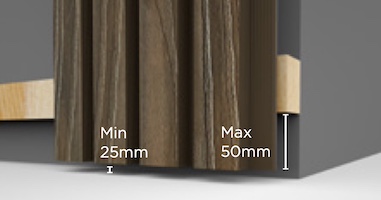

- A minimum of 25mm of continuous free area under the cladding surface is required for adequate ventilation.

- Before installation, make sure the supporting wall is flat and sound.

- A breathable vapour barrier should be installed behind joists to prevent water penetration.

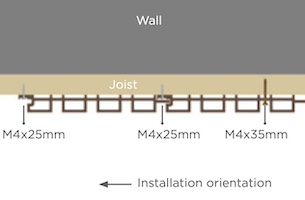

- Supporting joists should be a minimum of 25mm deep and 38mm wide.

- Fix joists to the wall at maximum of 450mm spacing with relevant anchor fixings.

- The spacing between anchors should be less than 500mm.

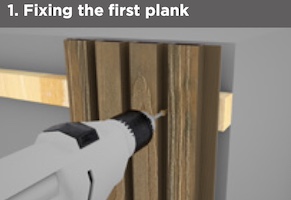

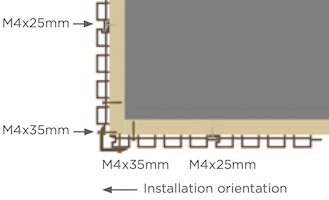

- Use a 35mm colour head screw through the low valley of the first cladding plank.

- Then, use a 25mm screw at the other side.

- When cladding above windows or doors, a colour coded steel drip trim should be installed to the joist to carry water away from the building.

- The spacing between screws should be 300mm maximum.

- Leave a 4mm expansion gap between the bottom of the cladding plank and the drip trim.

- For shallow window or door reveals it may be possible to just use the L corners on the two verticals either side of the window.

- Ensure adjoining corners are mitre cut for best finish.

- At the base of the window an L corner can be used only if there is not an existing sill is in place.

CHOOSE MANUFACTURERS

Brand: Bison Building Systems

Model and Size: 140mm x 2500mm - 0.35m2

Delivery Time: 2 - 5 working days

12mm Bison Composite Batten Cladding Edge Board is an elegant wood plastic composite cladding edge plank with a timber look that can be used to finish and close a side. It is available in two colours: Ash Grey or Oak, with a lifelike woodgrain timber finish. Bison Composite Batten Cladding Edge..

Guide Price: £15.95

£19.14 inc VAT

Brand: Bison Building Systems

Model and Size: 219mm x 2700mm - 0.54m2

Delivery Time: 2 - 5 working days

26mm Bison Composite Batten Cladding Plank is an elegant wood plastic composite cladding planks with a timber look that can be installed vertically or horizontally. It is available in two colours: Ash Grey or Oak, with a lifelike woodgrain timber finish. It is a low maintenance, UV stable and r..

Guide Price: £21.88

£26.26 inc VAT

Brand: Bison Building Systems

Model and Size: 56mm/51mm x 2500mm

Delivery Time: 2 - 5 working days

Bison Composite Batten Cladding L-Corner is an elegant wood plastic composite cladding corner board with a timber look that can be used to finish and close a corner. It is available in two colours: Ash Grey or Oak, with a lifelike woodgrain timber finish. Bison Composite Batten Cladding Edge Bo..

Guide Price: £9.51

£11.41 inc VAT

Brand: Bison Building Systems

Model and Size: 2000m

Delivery Time: 2 - 5 working days

Bison Composite Batten Cladding Steel Drip Trim is to be used above window and door reveals to carry water away from the building. It can also be used at the bottom of cladding to create drip edge. Available in Brown and grey. Powder coated.CHARACTERISTICSHidden Leg: 20mm,Kickout leg: 30m..

Guide Price: £14.93

£17.92 inc VAT

Brand: Bison Building Systems

Model and Size: M4 - 100nos

Delivery Time: 2 - 5 working days

Bison Composite Batten Cladding Colour Screws to be used on any visible batten clad fixings and for corners or edge boards. CHARACTERISTICS35mm long Diameter: 4mmColour: Brown or GreyCountersunk Pozi head..

Guide Price: £10.20

£12.24 inc VAT

Brand: Bison Building Systems

Model and Size: M4 - 100nos

Delivery Time: 2 - 5 working days

Bison Composite Batten Cladding Fixing Screws to be used hidden on the lap detail of the cladding plank to timber or light gauge steel.CHARACTERISTICS25mm long Diameter: 4mmCountersunk Pozi head..

Guide Price: £6.13

£7.36 inc VAT

Showing 1 to 6 of 6 (1 Pages)